Installation Guide for an Infant Diaper Production Line. Step 1: Preparing the Installation Area. Step 2: Unpacking and Inventory Check. Step 3: Assembling the ...

Introduction. 1. Automated Material Handling. 2. Continuous Production Flow. 3. Quality Control Measures. 4. Efficient Machine Maintenance. 5. Skilled Workforce...

1. Capacity and Efficiency. 2. Product Quality. 3. Flexibility and Customization. 4. Energy Efficiency. 5. Reliability and Maintenance. 6. Cost-effectiveness. 7...

Introduction. Market Trends. Growth Factors and Challenges. Conclusion....

1. Raw Material Selection and Preparation. 2. Diaper Assembly. 3. Quality Control and Packaging....

Introduction. 1. Meeting Market Demand. 2. Ensuring Hygiene Standards. 3. Enhancing Comfort. 4. Customization Options. 5. Cost-Efficiency. 6. Environmental Sust...

Introduction. Benefits of Infant Diaper Production Lines. Production Process. Market Trends....

Introduction. Key Components of Infant Diaper Production Line. Manufacturing Process. Quality Control Measures....

In daily work, infant diaper production line maintenance and repair personnel must not only have high-level technology, but also master relevant theoretical kno...

the diaper production machine is an essential tool in the disposable diaper industry. Its automated process, high production capacity, and customizable settings enable manufacturers to ...

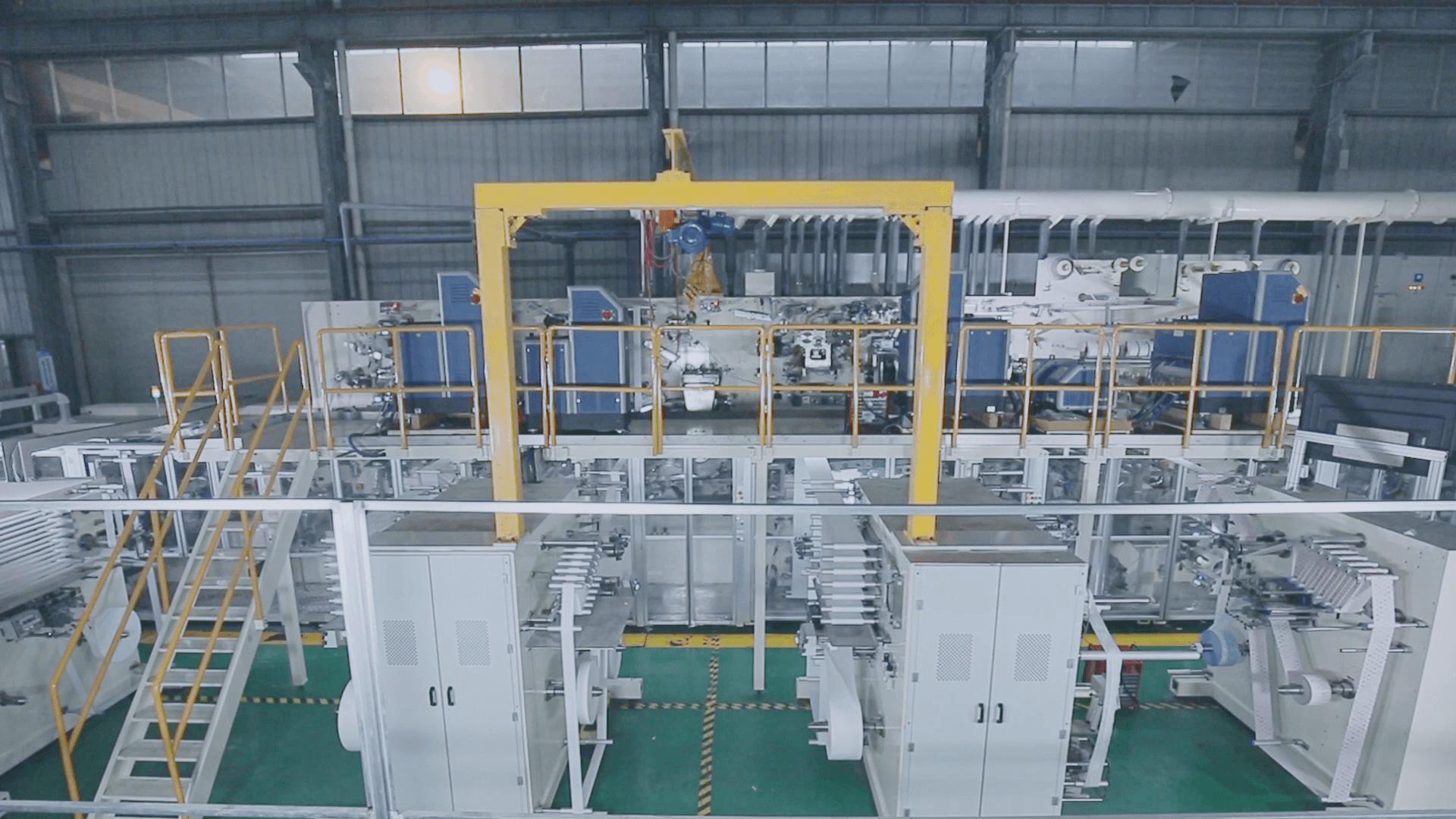

The U-Shape Baby Diaper Production Line incorporates advanced technology and engineering expertise to provide a comprehensive solution for diaper manufacturers....

Pampers Nappies Manufacturers South Africa. This machine design speed is 700pcs/minm,stable working speed is 600pcs/min. This machine is lastest technology from Haina Machinery which ...

Thisis HAINA high speed baby pull-ups for one renowned customer in Philippines. Itis able to produce baby pull-ups in six sizes, size NB/S/M/L/XL/XXL. Stableworking speed 800pcs/min f...