1. Increased Productivity. 2. Enhanced Quality Control. 3. Customization and Innovation. 4. Environmentally Friendly Diapers. 5. Cost Efficiency. 6. Enhanced Sa...

1. Regular Cleaning and Inspection. 2. Lubrication and Calibration. 3. Staff Training and Safety Measures....

1. Market Trends. 2. Market Challenges. 3. Market Opportunities....

Introduction. Market Size and Growth. Key Market Factors. Conclusion....

Introduction. Market Trends. Growth Factors and Challenges. Conclusion....

Introduction. 1. Raw Material Selection. 2. Equipment Calibration and Maintenance. 3. Quality Control and Testing. Conclusion....

1. Raw Material Selection and Preparation. 2. Diaper Assembly. 3. Quality Control and Packaging....

Introduction. Market Trends. Competitive Landscape. Consumer Preferences....

Introduction. Production Planning and Scheduling. Equipment Maintenance. Waste Management. Conclusion....

Introduction. Raw Materials. Production Process. Quality Control. Conclusion....

Enhanced Production Efficiency. Quality Assurance. Innovative Design and Sustainability....

Introduction. 1. Meeting Market Demand. 2. Ensuring Hygiene Standards. 3. Enhancing Comfort. 4. Customization Options. 5. Cost-Efficiency. 6. Environmental Sust...

1. Regular Cleaning and Sanitization. 2. Regular Inspection and Maintenance. 3. Staff Training and Safety Measures....

Introduction. Design Considerations. Materials Used. Quality Control Measures....

1. Routine Cleaning and Inspection. 2. Lubrication and Maintenance of Moving Parts. 3. Calibration and Quality Control Measures....

Introduction. Benefits of Infant Diaper Production Lines. Production Process. Market Trends....

Introduction. 1. Raw Material Handling and Preparation. 2. Diaper Assembly. 3. Quality Control and Packaging. Conclusion....

1. Baby Diapers: Ensuring Comfort and Convenience. 2. Adult Incontinence Products: Promoting Dignity and Confidence. 3. Environmental Sustainability: Embracing ...

Introduction. Key Components of Infant Diaper Production Line. Manufacturing Process. Quality Control Measures....

Introduction. Raw Materials. Production Process. Quality Control....

1.Adult Menstrual PantsMachine Program System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, automatic we...

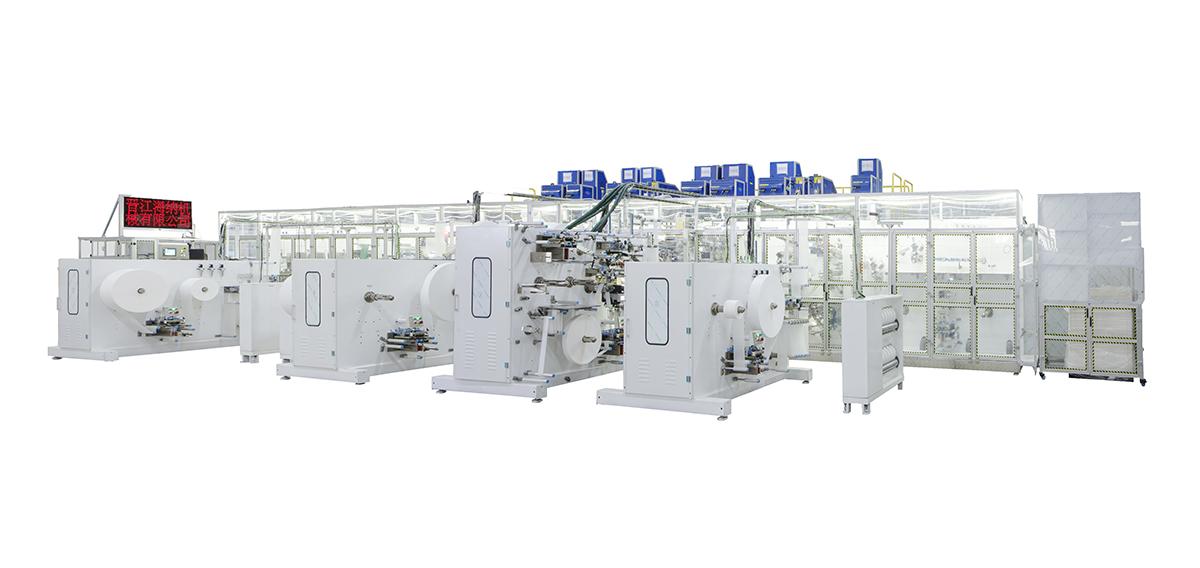

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, e...

1.Automatic Menstrual Pants MachineProgram System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, automatic ...

Thisis HAINA adult diaper machine, it is compatible with S cut ear tape and T shapebig ear tape. Itis able to produce adult diaper in three sizes, size M/L/XL Stableworking speed 30...

This is Haina Adult Diaper Production Line for Fujian Laoyoufu Customer Stable working speed :250 pcs/min The customer purchased machine from Haina in 2020,Adult Diaper are commonly used...

diaper machine to ensure the continuity and stability of enterprise production and the smooth realization of economic benefits, environmental benefits and safety benefits...

900 L diapers per minute? Yes, this line can do it!...