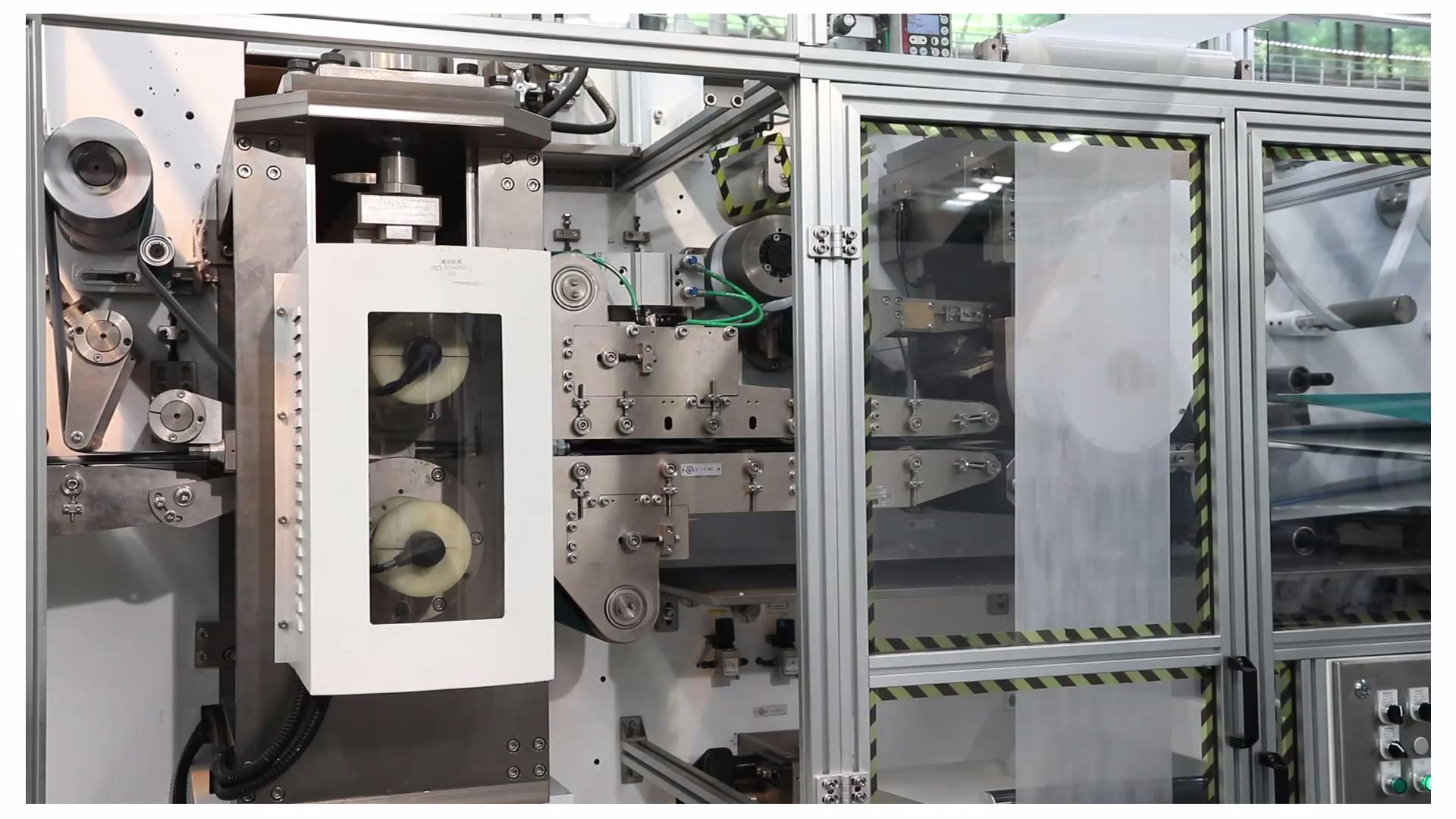

Sanitary napkin production line is an efficient and advanced manufacturing system that is designed to produce high-quality sanitary napkins for women. This production line is equipped with various machines and equipment, such as raw material unwinding machine, embossing unit, SAP application unit, folding unit, wing press unit, and wrapping unit.

Menstrual Lady Pad Machine is an expensive machine, but the production benefits it brings can greatly exceed its cost, so more and more people are engaged in this industry.

One of the key features of this production line is its ability to produce different types of sanitary napkins, such as ultra-thin, regular, and overnight napkins, by simply changing the settings of the machines. Additionally, this production line offers flexible production capacities to meet the demands of various customers.

The sanitary napkins produced by this production line are made using high-quality raw materials, such as cotton, pulp, and superabsorbent polymer (SAP), which provides excellent absorbency and protection during menstruation. Furthermore, the production process is fully automated, which ensures consistent quality and reduces the risk of human error.

Another important aspect of this sanitary napkin production line is its eco-friendly design. The process generates less waste and the final products are biodegradable, making them safe for the environment.

In summary, the sanitary napkin production line is an efficient, flexible, eco-friendly, and reliable system that produces high-quality sanitary napkins for women.

Automatic Lady Pad Machine

|

Dimensions(L×W×H8) |

45m*10m*4m |

|

Design Speed: |

350ppm |

|

Stable Working Speed: |

250-300ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

400KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

95 tons |

Automatic Menstrual Lady Pad Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

Menstrual Pants Machine a one-time investment that pays off in the long run.Noah 2024-05-31

It's a revolutionary product that has simplified my menstrual care routine.John 2024-05-31

As a business owner, the Menstrual Pants Machine has allowed me to offer a unique and valuable service to my customers.Jackson 2024-05-31

It's user-friendly and requires minimal effort to keep it running smoothly.Michael 2024-05-31