8.Automatic Menstrual Pants Making Machine Customized Function Available.

Menstrual Lady Pad Machine is an expensive machine, but the production benefits it brings can greatly exceed its cost, so more and more people are engaged in this industry.

Automatic Lady Pad Machine

|

Dimensions(L×W×H8) |

45m*10m*4m |

|

Design Speed: |

350ppm |

|

Stable Working Speed: |

250-300ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

400KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

95 tons |

Automatic Lady Pad Machine Product Description:

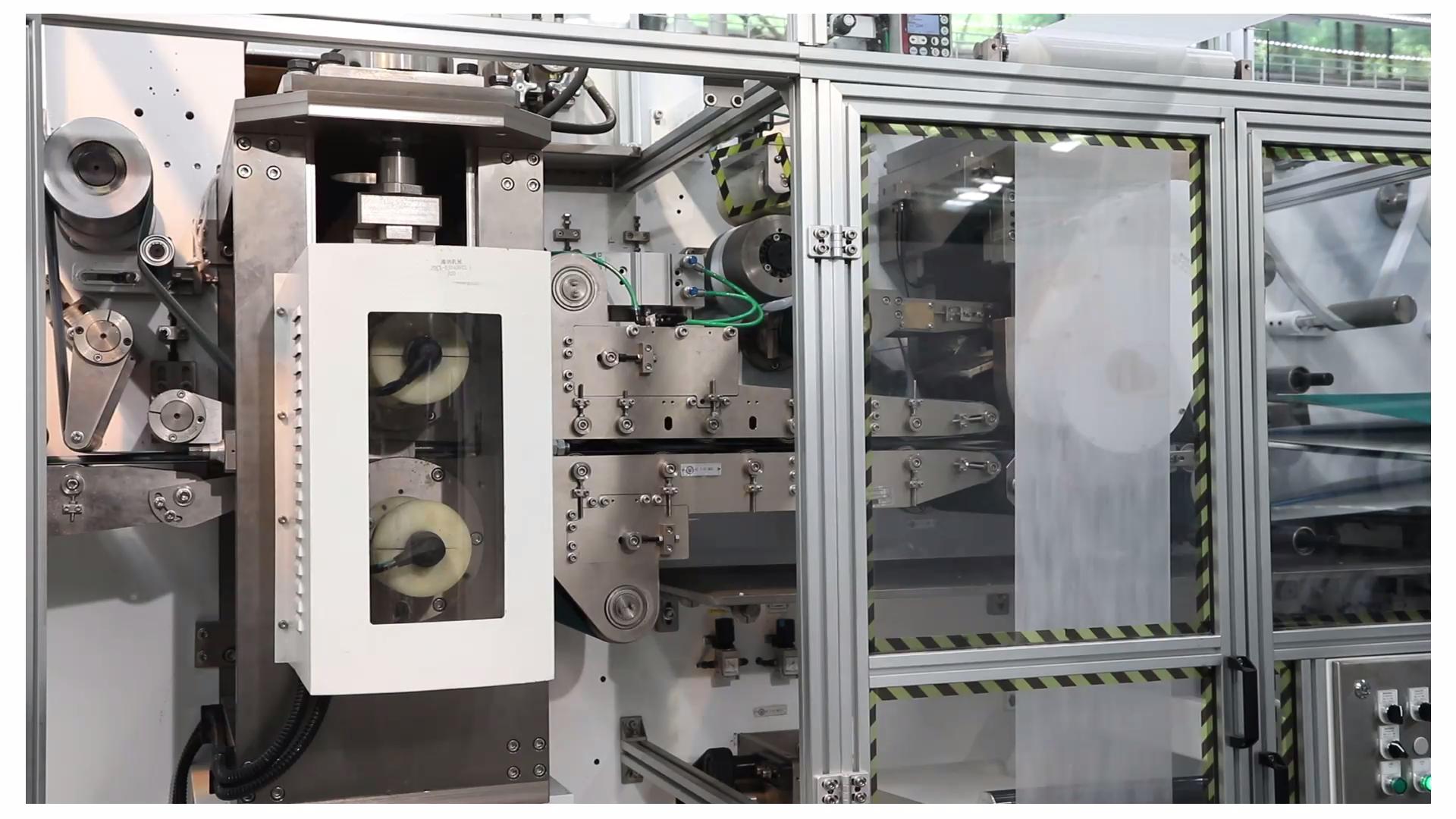

The Automatic Lady Pad Machine is a cutting-edge manufacturing solution designed to produce high-quality and hygienic sanitary pads for women. This advanced machine is equipped with state-of-the-art technology and features to ensure efficient and precise production processes. With its user-friendly interface and automated functionalities, it offers an innovative solution for the manufacturing of lady pads.

Automatic Lady Pad Machine Technical Features:

1.High-Speed Production: The Automatic Lady Pad Machine utilizes advanced mechanisms and precision control systems to achieve high-speed production, ensuring a rapid and uninterrupted manufacturing process.

2.Customizable Design: This machine allows for the production of sanitary pads in various shapes, sizes, and absorbency levels, meeting the diverse needs of women.

3.Quality Control System: The machine is equipped with a comprehensive quality control system that monitors every step of the production process, guaranteeing the production of safe and reliable sanitary pads.

4.Efficient Material Usage: The Automatic Lady Pad Machine optimizes material usage, reducing waste and maximizing productivity. Product Application:The Automatic Lady Pad Machine finds wide applications in the hygiene industry. It can be used in large-scale manufacturing facilities, as well as small and medium-sized enterprises producing sanitary pads.Its versatility allows for the production of different types of sanitary pads suited for daily use, overnight protection, or specific needs such as maternity pads.

Automatic Lady Pad Machine Key Functions:

1.Cutting and Shaping: The machine precisely cuts and shapes the materials to create the desired shape and size of the sanitary pads.

2.Absorbent Core Placement: It accurately places the absorbent core layer within the pad, ensuring optimal absorption performance.

3.Adhesive Application: The machine applies adhesive to attach the different layers of the sanitary pad securely.

Automatic Lady Pad Machine Individual Packaging:

It provides efficient packaging solutions, ensuring the sanitary pads are hygienically sealed and ready for distribution. Note:

1.Proper maintenance and regular cleaning of the machine are essential to ensure its optimal performance and longevity.

2.Operator training is recommended to maximize the efficiency and safe operation of the Automatic Lady Pad Machine.

3.All safety precautions should be followed during the operation of the machine to prevent accidents and injuries.

4.Compliance with hygiene standards and regulations is crucial to guarantee the production of sanitary pads that meet industry requirements.

In summary, the Automatic Lady Pad Machine is a technologically advanced solution for the efficient and precise manufacturing of high-quality sanitary pads. With its customizable design, high-speed production capabilities, and comprehensive quality control system, it offers a reliable and versatile option for businesses in the hygiene industry.

Automatic Menstrual Lady Pad Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | Waist inner NW |

| 11 | Waist outer NW |

| 12 | Elastic for waist |

| 13 | Construction glue |

| 14 | Elastic glue |

| 15 | Wetness indicator glue |

It's user-friendly and requires minimal effort to keep it running smoothly.Michael 2024-05-31

I love how the Menstrual Pants Machine has reduced my environmental impact by eliminating the need for disposable products.Logan 2024-05-31

The quality of the menstrual pants produced by this machine is top-notch.Luna 2024-05-31

As a business owner, the Menstrual Pants Machine has allowed me to offer a unique and valuable service to my customers.Jackson 2024-05-31