1. Automated Production Process. 2. Versatile Product Range. 3. Cost Efficiency. 4. Improved Product Quality. 5. Enhanced Production Capacity. 6. Customization ...

Introduction. 1. Raw Material Preparation. 2. Core Formation. 3. Top Sheet and Bottom Sheet Production. 4. Acquisition and Distribution Layer (ADL) Addition. 5....

Introduction. 1. Choosing the Right Equipment. 2. Layout Planning. 3. Electrical and Mechanical Integration. 4. Operator Training. 5. Quality Control Systems. 6...

1. Components. 2. Processes. 3. Quality Control....

Introduction. Maximizing Production Output. Reducing Waste and Costs. Conclusion....

Streamlined Manufacturing Process. Improved Product Quality. Cost Efficiency and Sustainability....

baby diaper making production line The three-level maintenance system is a mandatory maintenance system that focuses on the maintenance of the equipment and pay...

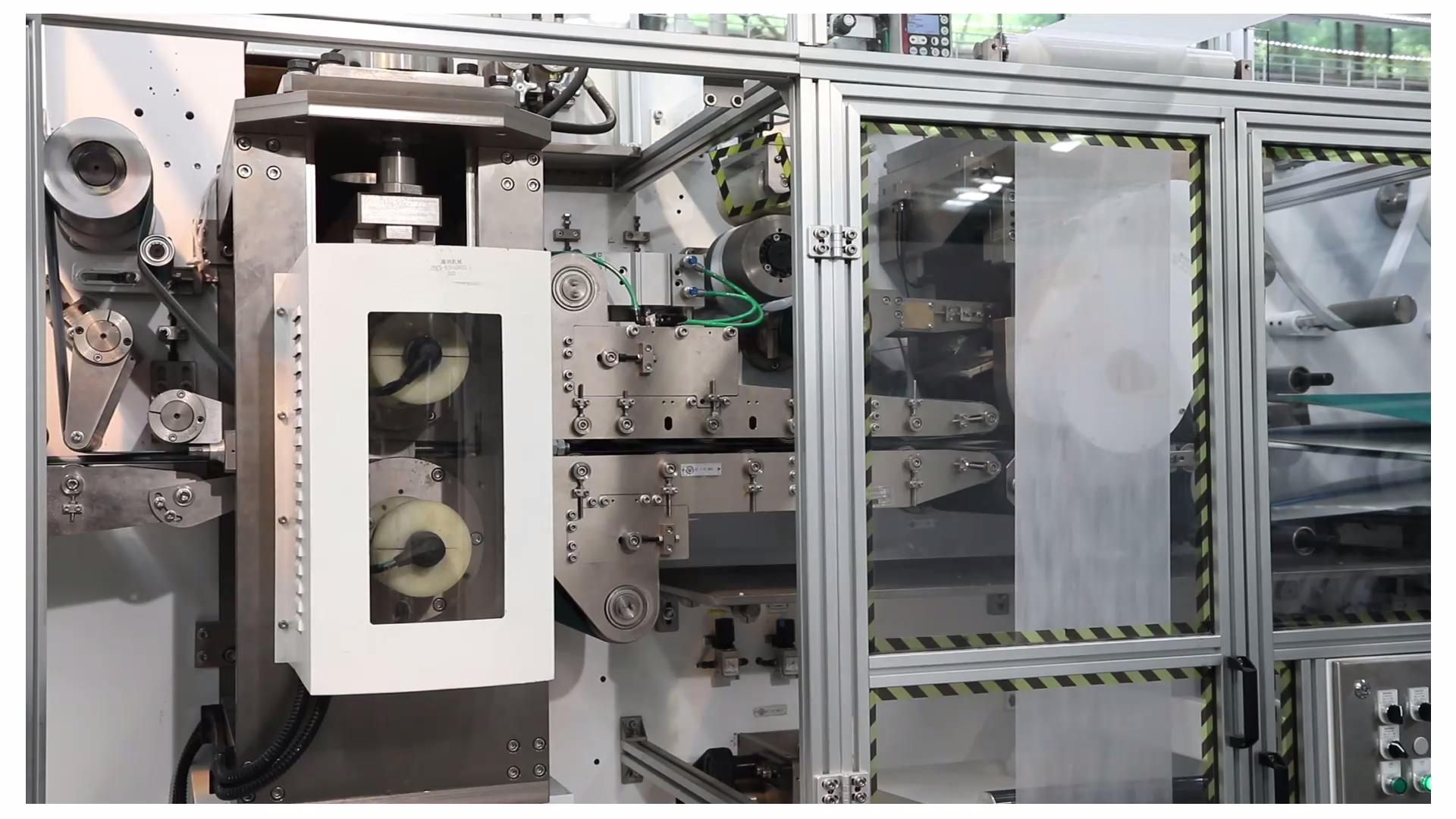

Baby diaper making production line is the main equipment of production. It keeps the machinery in good technical condition and gives full play to the best effic...

the diaper production machine is an essential tool in the disposable diaper industry. Its automated process, high production capacity, and customizable settings enable manufacturers to ...

The U-Shape Baby Diaper Production Line incorporates advanced technology and engineering expertise to provide a comprehensive solution for diaper manufacturers....

Adult Diaper Machine Price here. This machine is able to produce adult diaper in five sizes, size S/ M/L/XL /XL. Stable working speed 350pcs/min for Msize. Product structure: Middle...

It is able to produce baby pant in five sizes, size NB/ S/M/L/XL. Stable working speed 8 00pcs/min for M size . Compared with traditional baby pant machines in current marke...