Introduction. 1. Capacity and Output. 2. Automation and Control. 3. Material Compatibility. 4. Maintenance and Support. 5. Energy Efficiency. 6. Quality Assuran...

Introduction. 1. Production Capacity. 2. Machine Configuration. 3. Cost and Budget. 4. Machine Reliability. 5. Operator Training and Support. 6. Energy Efficien...

1. Regular Cleaning and Inspection. 2. Lubrication and Maintenance of Moving Parts. 3. Calibration and Performance Testing....

1. Regular Cleaning. 2. Lubrication and Inspection. 3. Preventive Maintenance....

Introduction. Current Market Trends. Key Players in the Industry. Future Prospects....

Introduction. Current Market Size. Key Players and Technological Advancements. Conclusion....

Introduction. Growing Demand for Diaper Manufacturing Machines. Key Market Trends and Opportunities. Conclusion....

Introduction. Growing Demand for Automated Machinery. Technological Advancements and Innovation. Challenges and Opportunities....

Introduction. Machine Setup and Configuration. Operational Parameters and Control. Quality Assurance and Product Inspection. Conclusion....

Introduction. Machine Components and Features. Production Process and Machine Operation. Quality Control and Troubleshooting....

1. Market Demand. 2. Technological Advancements. 3. Market Trends....

1. Increased Production Capacity. 2. Improved Product Quality. 3. Enhanced Customization Options. 4. Cost Efficiency. 5. Sustainability and Eco-Friendliness. 6....

Introduction. Streamlining Production Processes. Proactive Maintenance and Upkeep. Continuous Improvement and Training. Conclusion....

1. Efficient Production Process. 2. Customization and Flexibility. 3. Quality Control and Hygiene Standards....

Introduction. Improved Efficiency and Productivity. Enhanced Quality and Consistency. Cost Savings and Sustainability. Conclusion....

Introduction. Automated Production Line. Continuous Monitoring and Maintenance. Optimized Production Planning. Conclusion....

Introduction. Machine Efficiency and Capacity. Quality and Customization. Automation and Maintenance....

Introduction. 1. Raw Material Selection. 2. Machine Settings and Operation. 3. Quality Control and Testing. Conclusion....

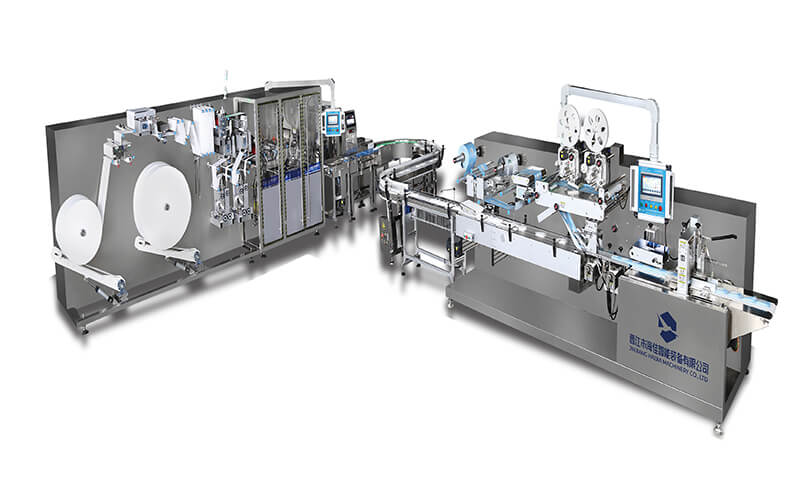

Introduction. Functionality of Infant Diaper Manufacturing Machines. Key Components of Infant Diaper Manufacturing Machines. Maintenance Requirements. Conclusio...

Introduction. Benefits of Efficient Diaper Manufacturing Machines. Maximizing Performance of Diaper Manufacturing Machines. Conclusion....

The Feminine Sanitary Napkins Machine is a state-of-the-art piece of equipment designed for the efficient and automated production of feminine sanitary napkins....

1. U-Shape Baby Pull-ups Diaper Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Driven System Servo drive, digital size change, ensure run syn...

1 Material: Spunlace nonwoven fabric, calender bonded nonwoven fabric etc. 2 Material Basic Weight: 35-80g/m ² 3 Jumbo Roll Spec.: Max W205*2( same paper core)mm*Φ1200mm ...

This is Pull up Baby Diaper Machine in Saudi Arabic. This machine can produce 4 sizes, M/L/XL/XXL for the market and now this pull up baby diaper is more and more popular in Saudi Arab...

This is Haina Baby Diaper Manufacturing Machine in Malaysia, It can produce four sizes of S / M / L / XL, with a stable production speed of 500 pieces / min. The shape of baby pants is ...

In order to adapt to the production development of enterprises, enterprises often have to design and manufacture some efficient special mini sanitary pad making machine, which is a good...

diaper machine to ensure the continuity and stability of enterprise production and the smooth realization of economic benefits, environmental benefits and safety benefits...