|

1 |

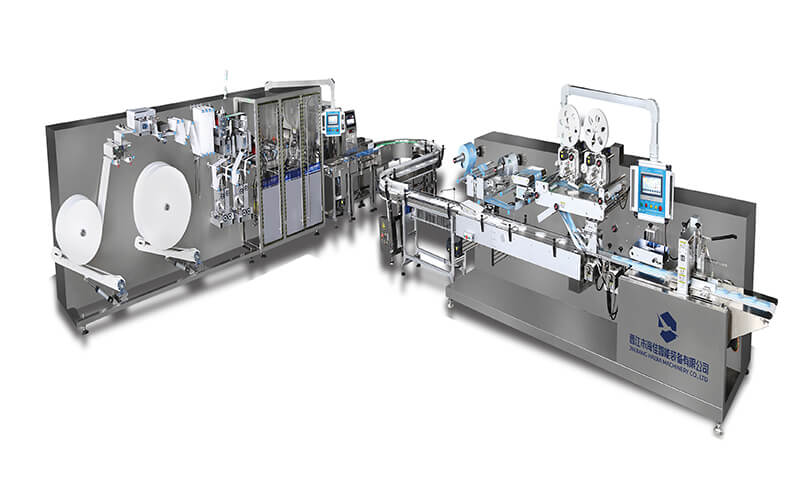

Material: Spunlace nonwoven fabric, calender bonded nonwoven fabric etc. |

|

|

2 |

Material Basic Weight: 35-80g/m² |

|

|

3 |

Jumbo Roll Spec.: Max W205*2( same paper core)mm*Φ1200mm |

|

|

4 |

Jumbo Roll Axis: 2 axis of jumbo rolls, splicing without stopping the machine, core dia.: 3'' |

|

|

5 |

Unfold Dimension: L140-200mm, W130-205mm |

|

|

6 |

Fold Dimension: L70-100mm, W38-70mm |

|

|

7 |

Folding Type: V fold, N fold, 1/2 fold |

|

|

8 |

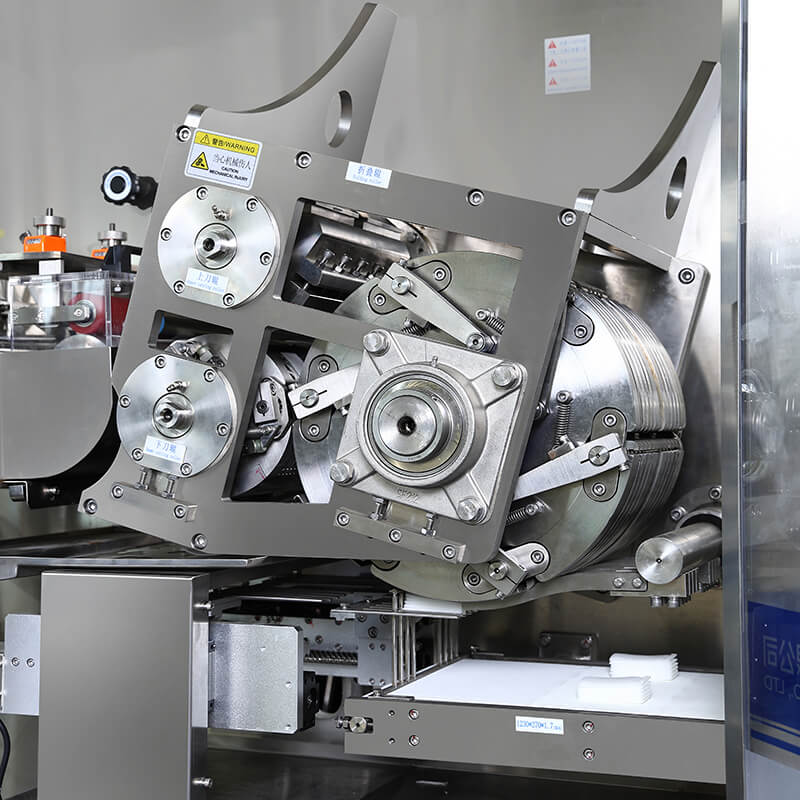

Slitting: screw cutting, 6 pcs of cutting knives, lower the noise, longer the service life of knives |

|

|

9 |

Production Parameters: |

1) Stack quantity: 5-30 pieces ( height ≤ 60mm) |

|

2) Production Speed: 80 bags/min ( for 10 pcs) |

||

|

3) Production Speed: 50 bags/min ( for 20 pcs) |

||

|

4) Splicing joints detection, auto rejection |

||

|

10 |

Liquid Adding Method: |

1) Immersion or spray type, as per different materials |

|

2) 2.5-4 times liquid adding detection, set the liquid weight by touch screen |

||

|

3) Real-time detection of liquid bucket level, set the alarm position of liquid by touch screen |

||

|

4) 650L stainless steel hygienic grade water tank |

||

|

11 |

Control Method: |

1) Multi-axis controller, driven by servo motor |

|

2) 10 inches touch screen, easy for operation |

||

|

3) Stacking controlled by independent servo, ensure neat stack and splicing joints rejection |

||

|

12 |

Machine Size: L 6180 x W1300 x H2100 mm |

|

|

13 |

Machine Power: AC380V (customizable), 50/60Hz, three phases five wires, 11KW |

|

|

14 |

Air Supply: 0.6-0.8Mpa, 130L/min |

|

|

15 |

Machine Weight: about 3000KG |

|

|

16 |

Optional devices: online slitting, web guide controller, metal& weight detection and rejection device |

|