1. Enhanced Efficiency. 2. Cost-Effectiveness. 3. Customization Options....

1. Regular Cleaning. 2. Lubrication. 3. Inspection and Replacement of Parts....

Introduction. Enhanced Efficiency and Productivity. Customization and Innovation. Environmental Sustainability. Conclusion....

1. Market Overview. 2. Key Challenges. 3. Emerging Opportunities....

1. Current Trends in the Baby Diaper Machine Industry. 2. Key Players and Market Size. 3. Future Prospects and Opportunities....

Regular Cleaning. Inspection and Lubrication. Calibration and Adjustment....

1. Components of a Baby Diaper Machine. 2. Operation of a Baby Diaper Machine. 3. Maintenance of a Baby Diaper Machine....

Introduction. Streamlining the Production Process. Investing in Advanced Technology. Employee Training and Skill Development. Conclusion....

1. Automated Production Process. 2. Cost-effective Operations. 3. Enhanced Product Quality....

Baby diaper machine . Maintenance work after failure refers to the process of repairing and maintaining the faulty equipment. Usually, the process of equipment ...

One of the characteristics of the equipmentmanagement of baby diaper machine enterprises in my country is to implement theequipment use and maintenance manageme...

With the continuous advancement of science and technology, the use of labor in production engineering is less and less, while the application of baby diaper mac...

Production is inseparable from machinery, and various equipment may be worn in daily production, and some faults will also be generated. To protect baby diape...

Baby diaper machine Loss of working ability is called failure, and the loss of specified working ability of machine parts is called failure. The failure of baby...

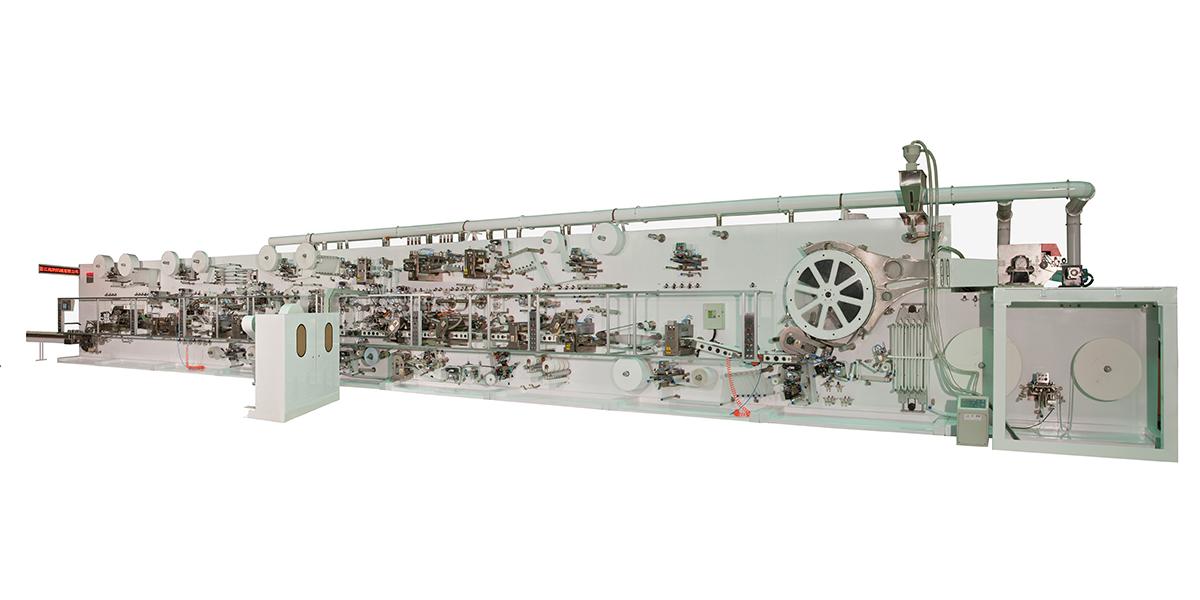

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully au...

1.Product structure: Upper lower tissue (or airlaid ), Cotton core (mix with SAP), ADL,PE flm, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophobic nonwoven, "S" cut side...

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, e...

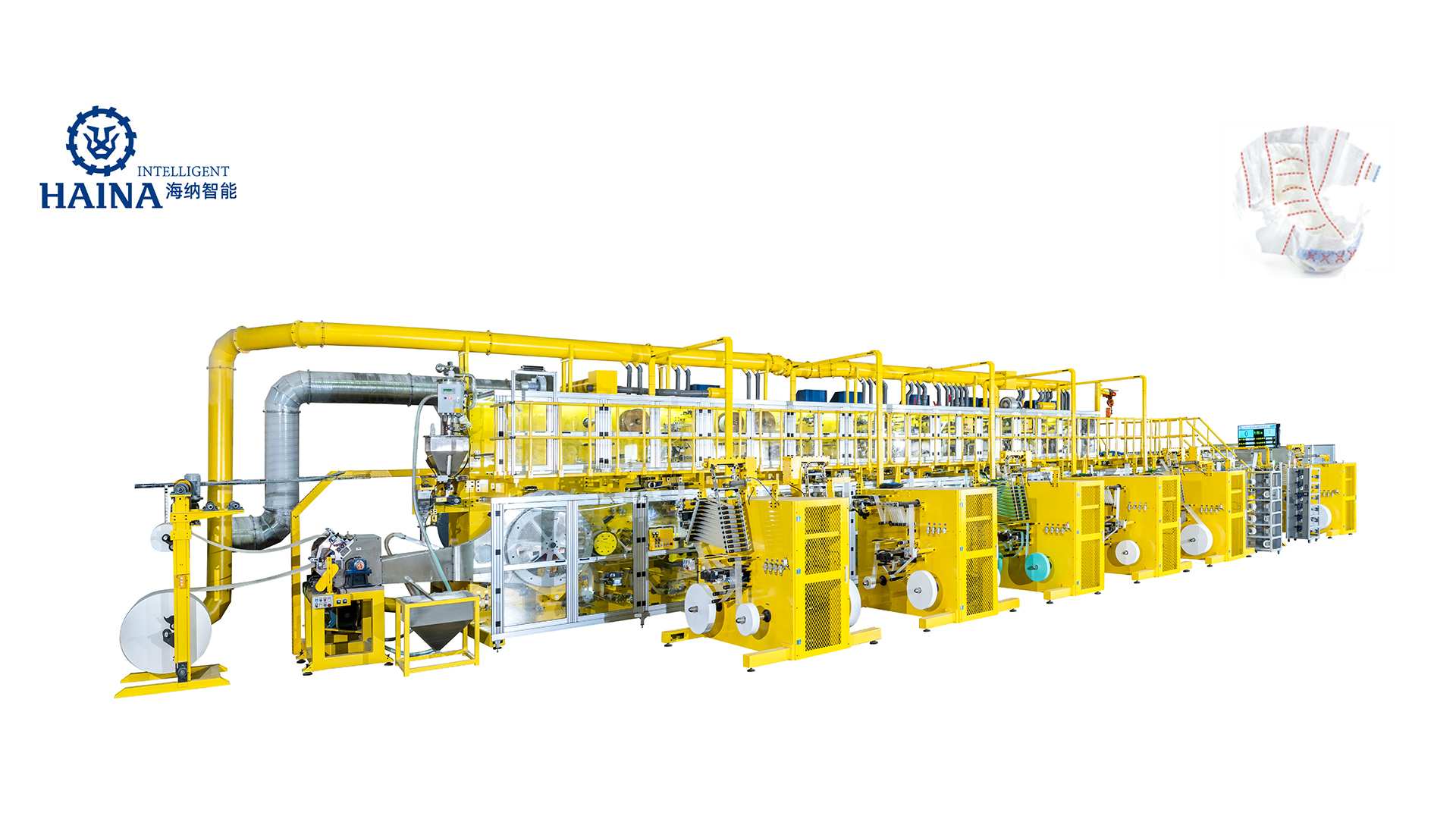

This baby diaper manufacturing equipment in Kenyais the third set of production line purchased by the customer from Haina. The design speed of this production line is 650 pieces and...

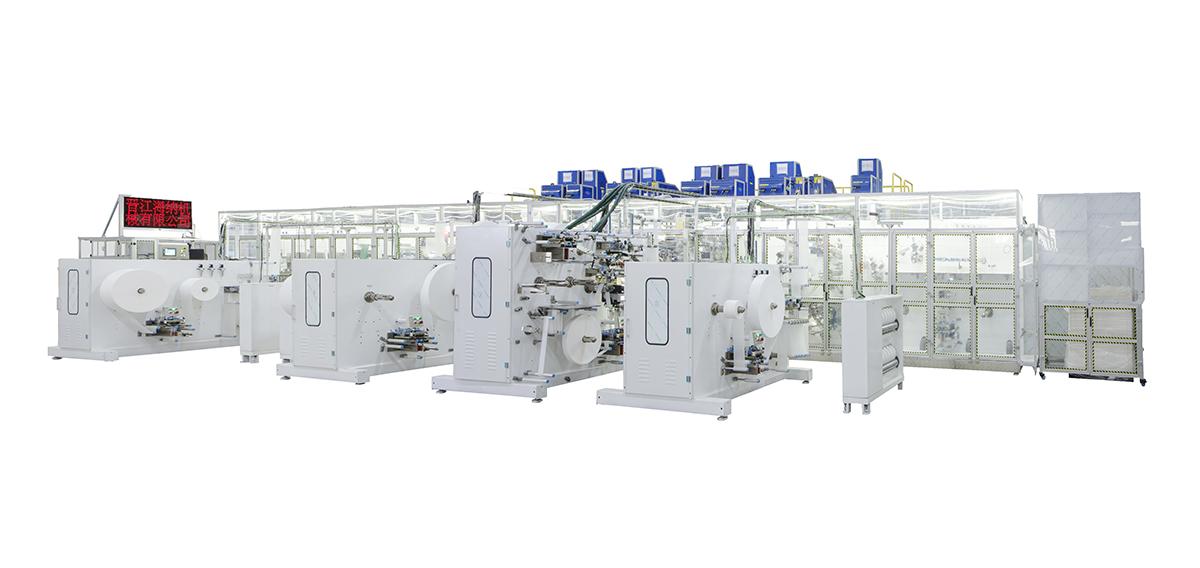

Diaper Production Line in Morocco, this machine designed speed is 700ppm for L size, stable working speed is 650ppm for L size and 600ppm fo XL size. The machine is very stable with hig...