Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-22

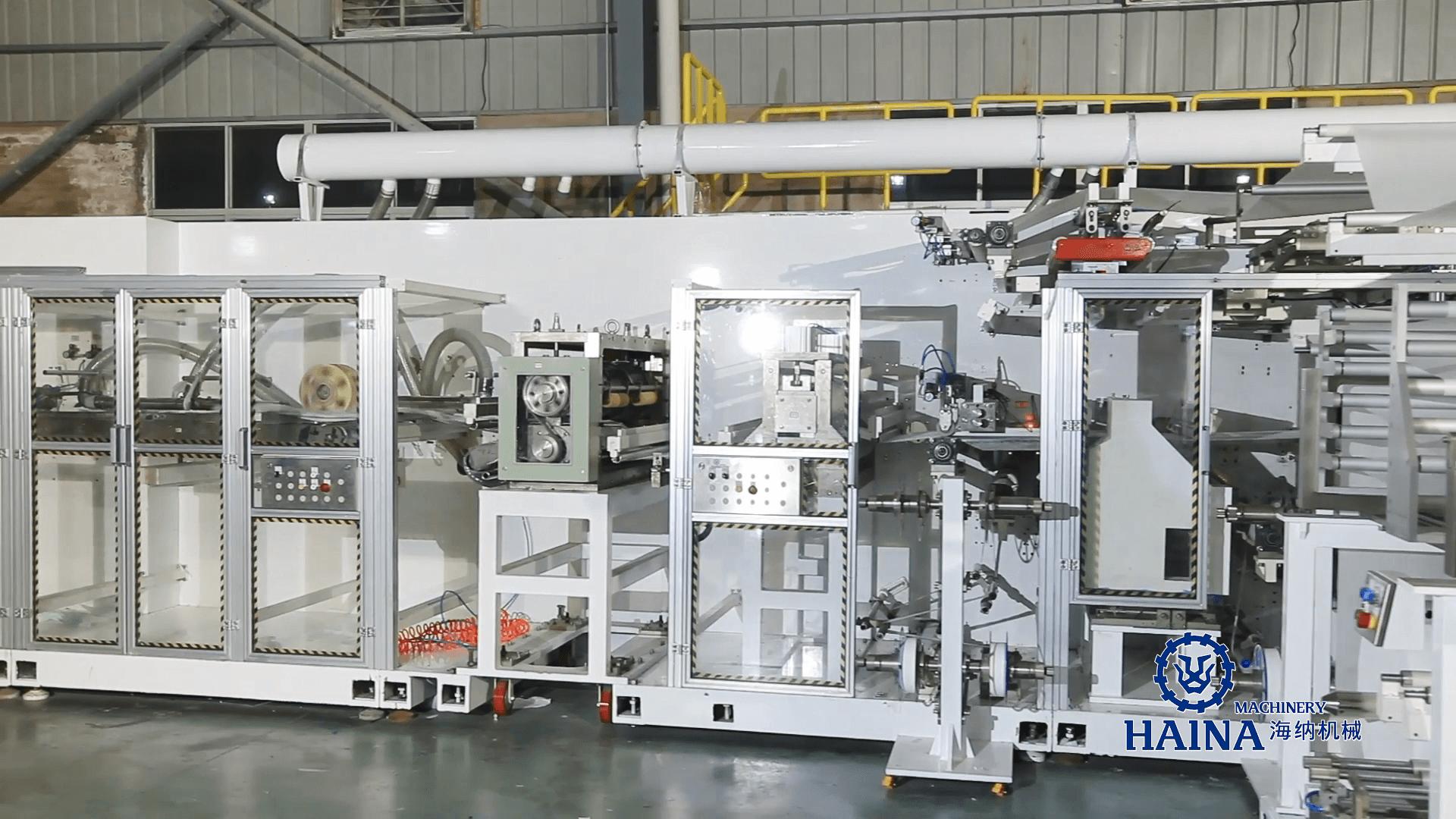

With the continuous advancement of science and technology, the use of labor in production engineering is less and less, while the application of baby diaper machine is more and more extensive, and modern production is more and more dependent on equipment. In the future, we will use more smart devices in engineering construction. Therefore, the importance of baby diaper machine maintenance in production is self-evident. This article summarizes the relevant points to provide reference for those who need it.

Some production units often fail to implement the maintenance system for machinery, and even directly ignore the equipment maintenance system after implementing the system of appointing people and machines. Some operators only pay attention to the use of equipment, and often ignore small problems that do not affect the use of equipment, which ultimately not only affects the service life of equipment and engineering quality, but also reduces production efficiency and delays production progress.

In this regard, it is necessary to formulate a regular maintenance system of different cycles for different equipment according to the wear pattern, use and even damage of parts with different configurations, combined with the conditions of use and referring to the requirements of the manual and relevant specifications, and strictly adopt graded maintenance according to this system. , maintenance measures.

The main work content of regular maintenance baby diaper equipment is to eliminate the faults and problems found, replace the parts that have used up their service life, check and adjust the vulnerable parts according to the situation, etc. According to the use time and workload of the equipment, regular maintenance measures of different complexity are taken. The higher the level, the greater the maintenance effort. The specific content of maintenance work at all levels should be formulated according to the conditions of different machines, but the requirements for maintenance work mainly include the following five points.

(1) Ensure that the machinery is in good operating condition and that all work indicators meet the specified requirements.

(2) Ensure that the operation is responsive and the safety device is reliable.

(3) Do a good job in cleaning, tightening, lubricating, adjusting and anti-corrosion maintenance.

(4) Ensure that all parts, accessories and tools are complete.

(5) Ensure complete and accurate records of mechanical use and maintenance data.

The formulation of graded repair measures for machines can generally be divided into project repairs, minor repairs, medium repairs and major repairs according to the wear and tear.

(1) Project repair is a general term for repairing the equipment whose wear state is close to the need for repair based on checking the operating state of baby diaper equipment. The purpose of extending the overhaul period is achieved through targeted, preventive and restorative maintenance of mechanical equipment.

(2) Minor repairs refer to maintenance repairs, which are used to solve faults and local damages during use and maintain the normal operation of the equipment. Corresponding work should be carried out according to the functions of the equipment and combined with maintenance measures.

(3) Medium repair is mainly aimed at the inspection and repair of large equipment before each transfer. It is necessary to replace the worn parts, check the parts with problems or suspected problems in detail, adjust the electrical control parts, and replace the circuits that have reached the service life.

(4) Overhaul means that most parts of a piece of equipment are about to reach the limit of wear and tear, and must be sent to the manufacturer for repair or entrusted to a qualified repair unit for repair and maintenance, so as to reduce the noise, vibration and environment generated during the production operation. pollute.

(1) Maintenance and repair by means of parts transposition can prolong the service life of machine parts.

(2) Relevant personnel must pay attention to the sound of the overflow valve and hydraulic pump when carrying out maintenance and repair of some production equipment. When the hydraulic pump emits the sound of cavitation, the cause must be found out and dealt with in time before continuing. Use; when an executive component moves slowly and has the sound of overflow valve overflowing under no-load state, it must be stopped immediately and repaired.

(3) When the equipment is operating on the production site, it is necessary to prevent hard objects from hitting the oil cylinder, piston rod and hydraulic oil pipe of the hydraulic equipment. If there are bump marks on the appearance of the piston rod, it must be checked immediately to prevent the sealing device from being damaged. On the premise of no oil leakage, it can continue to be put into operation.

(4) Strengthen the on-site personnel's awareness of the love of the machine. Relevant personnel should not use the machine roughly to avoid excessive impact load during the operation, which will increase the hidden danger of failure and affect the service life of the equipment.

(5) In winter, the temperature is low, and the conditions such as machine lubrication, cooling and fuel gasification are poor, and maintenance is difficult. Therefore, before each use, it should be checked in detail, and problems or hidden dangers should be dealt with in time. For machines that have been parked for a long time, the cooling water must be completely drained. In order to facilitate the start of the engine, an oil preheater should be installed.

baby diaper machine Administrators and production administrators are responsible for compiling the safety operation procedures for various machines, requiring professional maintenance personnel to stay on site and do a good job in technical disclosure of various configurations, prepare common and vulnerable parts on site, and check and maintain the equipment to ensure the safety of the equipment. operate.