1. Absorbency Level. 2. Material and Comfort. 3. Size and Fit. 4. Leakage Protection. 5. Washing and Care Instructions. 6. Brand Reputation. 7. Cost. 8. Sustain...

Step 1: Setup. Step 2: Loading. Step 3: Selecting Settings. Step 4: Initiating Cleaning Cycle. Step 5: Drying. Step 6: Removing Clean Period Panties. Step 7: Ma...

Introduction. 1. Customization Options for Enhanced Comfort. 2. Sustainable and Eco-Friendly Solution. 3. Cost-Effective Option. 4. Accessibility and Convenienc...

Period panties machine unlike other equipment, after using a certain period of time will lose its original use value, on the contrary, the more durable sanitary...

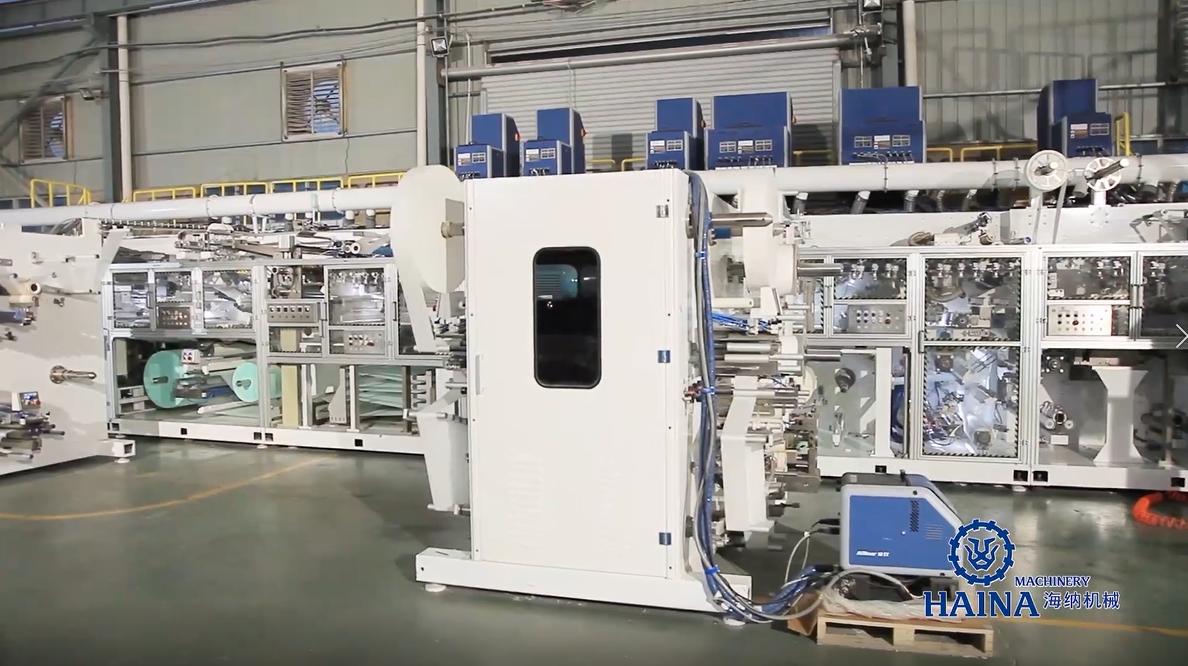

Period panties machines are generally repaired by special personnel. So what should we pay attention to when using the period panties equipment? 1. Precau...

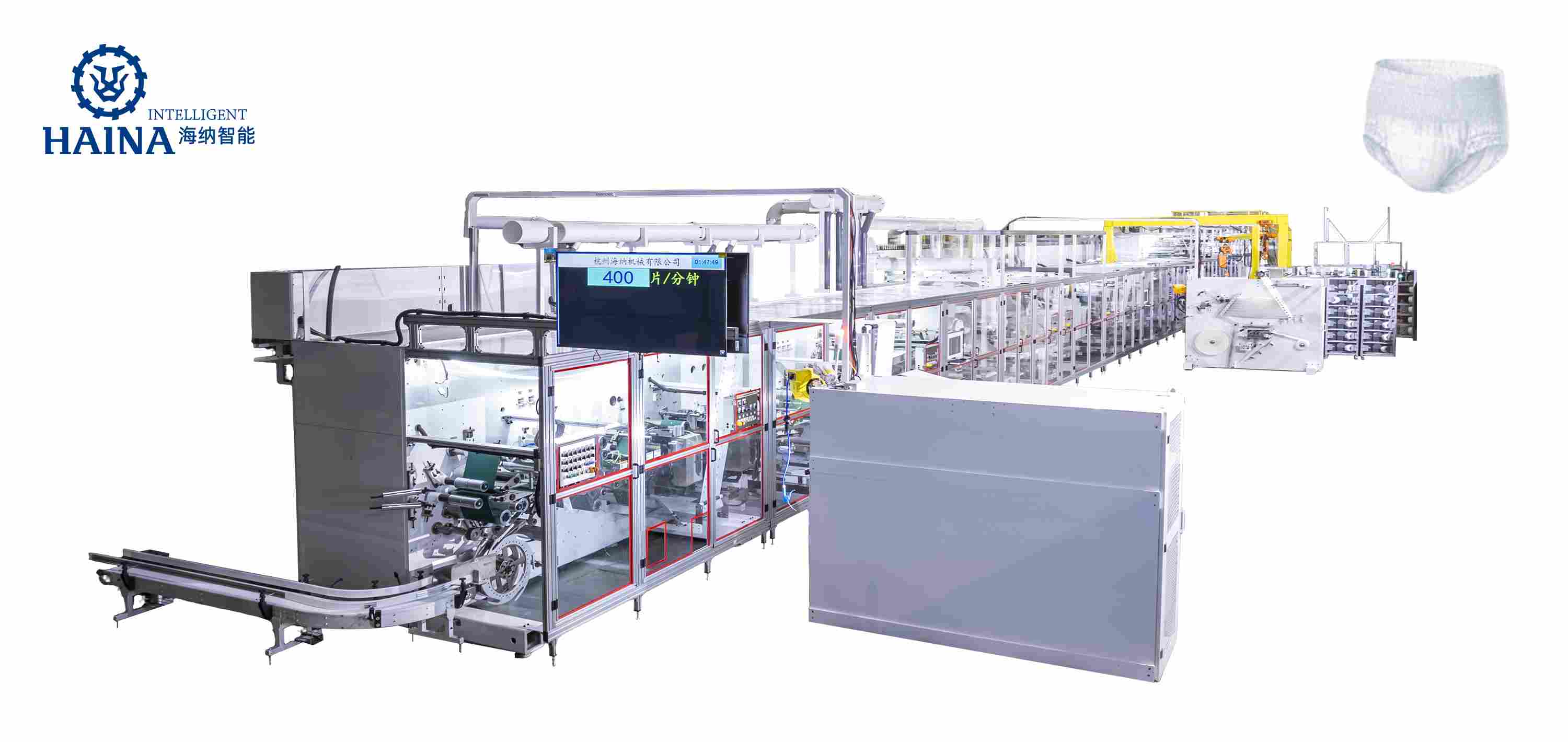

1.Automatic Menstrual Pants Making Machine Product structure: Upper lower tissue(or arlaid), Cotton core (mix with SAP), Topsheet hydrophilic nonwoven, ADL, Leak cuff hydrophobic...

Program system: Servo driven, intlligent HMI touch screen man-machine interface.Tension system: Tension control with buffer system, automatic web guiding system, to ensure materials sta...

Overall size: 30mx6mx3m(for reference only), Program system: Servo driven, intelligent HMl touch screen man-machine interface.Product structure: Flat(or textile edge)Topsheet, ADL(blue ...

Thisis HAINA high speed big waistband baby diaper machine for one South AsiaCustomer. Itis able to produce baby diaper in three sizes, size S/M/L/ Stableworking speed 800pcs/min for M...

Thisis HAINA high speed baby pull-ups for one renowned customer in Philippines. Itis able to produce baby pull-ups in six sizes, size NB/S/M/L/XL/XXL. Stableworking speed 800pcs/min f...