1.Product structure: Flat(or textile edge)Topsheet, ADL(blue core),Pulp or Airlaid core(mix with SAP),Backsheet, Absorbent paper,

Release paper, Pouch film, Fast-easy & package.

2.Product size:240mm, to be customized.

3.Program system: Servo driven, intelligent HMl touch screen man-machine interface.

4.Tension system: Tension control with buffer system, automatic web guiding system, to ensure materials stable working at ZERO speed splice.

6.Driven system: Servo drive, digital size change, ensure run synchronously at full process.

7.Safety system: Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

8.Auto Packing system: Auto stacker and packaging machine to be defined by customer need.

9.Web guiding system: GermanyBST/USA FIFE.

10.Customized function available

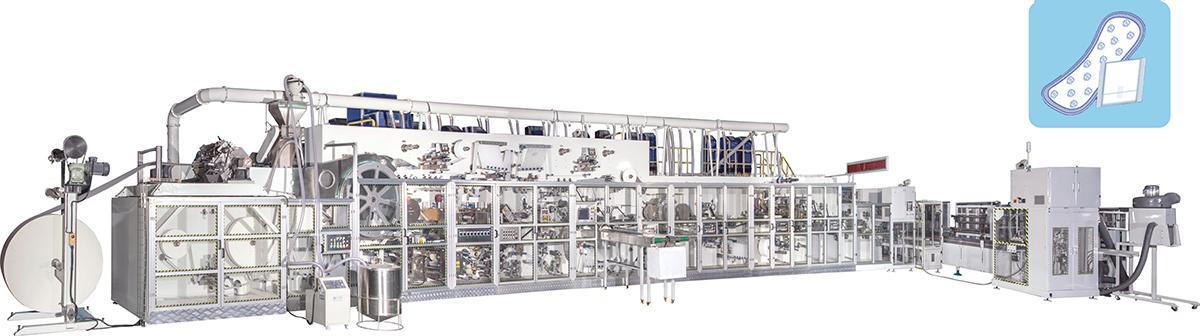

WSJ1000 Sanitary Pads Manufacturing Machine

|

Dimensions(L×W×H8) |

30m*6m*3m |

|

Design Speed: |

1500pcs per minute |

|

Stable Working Speed: |

1300pcs per minute |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

220KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

55 tons |

The sanitary pads manufacturing machine is a state-of-the-art piece of equipment designed to produce high-quality sanitary pads with maximum efficiency. This machine automates the entire process of pad production, including cutting, bonding, and shaping the pads. It is equipped with advanced sensors and control systems to ensure consistent and reliable production.

With a production speed of up to 100 pads per minute, this machine is capable of producing large quantities of sanitary pads in a short amount of time. The production rate can be adjusted depending on the specific needs of the manufacturer, and the machine can be configured to produce a range of pad sizes and shapes.

The sanitary pads manufacturing machine is designed with a user-friendly interface, making it easy to operate and maintain. It is constructed with high-quality materials that are resistant to wear and tear, ensuring durability and long-term use. Overall, this machine is an essential tool for manufacturers looking to streamline their production process and meet the demand for high-quality sanitary pads in the market.

| No. | Raw materials |

| 1 | Topsheet(NW or PPF) |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | ADL N.W. |

| 5 | Tissue |

| 6 | Backsheet |

| 7 | Back release paper |

| 8 | Wings release paper |

| 9 | Pouch film |

| 10 | Easy tape |

| 11 | Air laid paper |

| 12 | SAP Paper |

| 13 | Hydrophobic N.W. |

| 14 | Construction glue |

| 15 | Position glue |

1. Feminine Full Automatic sanitary napkin production line Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Tension Syst...

The Feminine Sanitary Napkins Machine is a state-of-the-art piece of equipment designed for the efficient and automated production of feminine sanitary nap...

Fully automatic sanitary pad machine is a highly advanced machine that is solely designed for the production of sanitary pads. This machine is designed to ...

The support team behind the Feminine Napkin Machine is top-notch,They provided excellent training and assistance when we needed itLaura M 2024-05-31

The quality of the feminine napkins produced by this Feminine Napkin Machine is unmatched. Our customers have given us great feedback since we made the switchEmily T 2024-05-31

The Feminine Napkin Machine is a game-changer for our business. It's efficient, reliable, and produces high-quality products consistentlyRachel W 2024-05-31

Our customers have noticed the difference in the quality of our feminine napkins since we started using this machine. Highly recommendedMegan H 2024-05-31