Fully automatic sanitary pad machine is a highly advanced machine that is solely designed for the production of sanitary pads. This machine is designed to ease the process of producing sanitary pads and to provide high-quality sanitary pads for women all over the world. This machine is equipped with advanced features that make it easy to use and highly efficient.

One of the main advantages of this machine is its fully automatic nature. It is designed to operate automatically without any human intervention. This makes it easy for manufacturers to produce sanitary pads faster and with higher precision. The machine is also equipped with advanced features such as an automatic tension control system, auto-stacking, and cutting systems that ensure the production of high-quality sanitary pads at a faster rate.

Another advantage of this machine is its flexibility. It can produce different sizes and shapes of sanitary pads to cater to the needs of different types of users, and it can adjust the thickness and shape of the pads as needed. This makes it easy for manufacturers to produce custom pads that meet the specific needs of their customers.

The fully automatic sanitary pad machine is also highly energy efficient. It is designed to minimize energy consumption, and its high-speed production capabilities ensure that the overall energy consumption is kept low.

In conclusion, the fully automatic sanitary pad machine is a highly advanced and efficient machine that offers a range of benefits to manufacturers. Some of the main benefits include its fully automatic nature, flexibility, and high efficiency. With its advanced features and capabilities, this machine is the perfect tool for producing high-quality sanitary pads that meet the specific needs of customers.

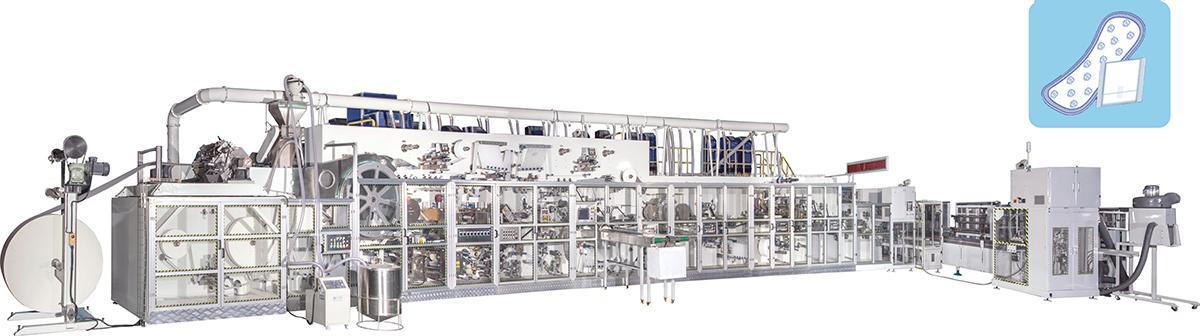

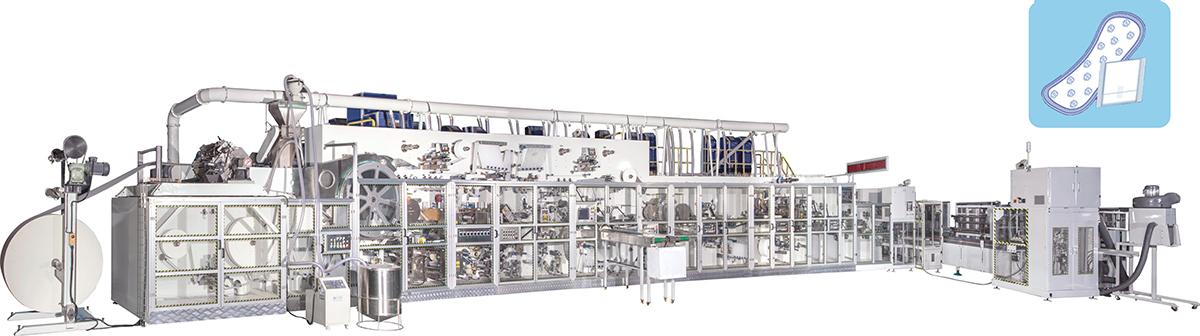

WSJ1000-fully automatic sanitary pad machine

|

Dimensions(L×W×H8) |

30m*6m*3m |

|

Design Speed: |

1000ppm |

|

Stable Working Speed: |

800-900ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

220KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

55 tons |

Fully Automatic Sanitary Pad Machine Product Description:

The Fully Automatic Sanitary Pad Machine is an innovative and advanced product designed to revolutionize the sanitary pad manufacturing industry. This cutting-edge machine combines state-of-the-art technology with precision engineering to produce high-quality sanitary pads efficiently and effortlessly.

Fully Automatic Sanitary Pad Machine Technical Features:

1. Automated Production: The fully automatic sanitary pad machine is equipped with advanced robotics and computerized systems, ensuring a seamless and uninterrupted production process. It eliminates the need for manual intervention, resulting in enhanced productivity and efficiency.

2. High Precision: With its precise measurement and control mechanisms, this machine ensures that each sanitary pad is manufactured with consistent quality and dimensions. The advanced sensors and feedback systems ensure minimal wastage and optimal material utilization.

3. Versatility: The machine is designed to accommodate various sizes, shapes, and designs of sanitary pads, making it highly versatile for different market requirements. It can be easily adjusted to produce different types of sanitary pads, including regular, overnight, and ultra-thin variants.

Fully Automatic Sanitary Pad Machine Product Application:

The Fully Automatic Sanitary Pad Machine finds wide application in the feminine hygiene industry. It enables manufacturers to produce sanitary pads on a large scale, catering to the growing demand for hygienic and high-quality menstrual products. The machine can be used by both established manufacturers and new entrants wanting to establish Fully Automatic Sanitary Pad Machine themselves in this market. Main Functions:

1. Material Feeding and Cutting: The machine precisely feeds and cuts the absorbent core, top sheet, and bottom layer materials to the required lengths, ensuring accurate dimensions and uniformity.

2. Core Assembly: It assembles the different layers of the sanitary pad, including the absorbent core, acquisition layer, and backsheet, in a precise and efficient manner. The machine ensures proper alignment and placement of each layer.

3. Sealing and Wrapping: The fully automatic sanitary pad machine seals the edges of the sanitary pads and wraps them individually, maintaining hygiene and preventing contamination. The sealed pads are packed into the final packaging, ready for distribution.

Fully Automatic Sanitary Pad Machine Precautions:

1. Regular Maintenance: It is essential to perform regular maintenance on the machine to ensure smooth operation and prevent any downtime. Cleaning, lubrication, and inspection of components should be carried out as per the manufacturer's guidelines.

2. Operator Training: Operators should be adequately trained to operate and maintain the fully automatic sanitary pad machine. This ensures proper handling, reduces the chances of errors, and maximizes productivity.

3. Safety Measures: The machine should be operated with proper safety precautions in place, such as emergency stop buttons, safety guards, and protective equipment, to prevent accidents and ensure the well-being of operators.

In conclusion, the Fully Automatic Sanitary Pad Machine offers a comprehensive solution for efficient and high-quality sanitary pad production. With its advanced technology, versatility, and precise functionality, this machine is an indispensable asset for manufacturers in the feminine hygiene industry.

WSJ1000-fully automatic sanitary pad machine

| No. | Raw materials |

| 1 | Topsheet(NW or PPF) |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | ADL N.W. |

| 5 | Tissue |

| 6 | Backsheet |

| 7 | Back release paper |

| 8 | Wings release paper |

| 9 | Pouch film |

| 10 | Easy tape |

| 11 | Air laid paper |

| 12 | SAP Paper |

| 13 | Hydrophobic N.W. |

| 14 | Construction glue |

| 15 | Position glue |

Fully automatic sanitary pad machine is a highly advanced machine that is solely designed for the production of sanitary pads. This machine is designed to ...

Overall size: 31mx4mx5m (for reference only). Product Structure: Flat(or textile edge)Topsheet,ADL(blue core), Tissue (or airlaid), Cotton core(mix with SA...

The Feminine Sanitary Napkins Machine is a state-of-the-art piece of equipment designed for the efficient and automated production of feminine sanitary nap...

This Feminine Napkin Machine is a workhorse! It's reliable, efficient, and has become an essential part of our production lineJessica S 2024-05-31

As a small business owner, I appreciate the durability and performance of this machine. Feminine Napkin Machine has exceeded my expectations in every way.Kimberly S 2024-05-31

I love how easy it is to operate the Feminine Napkin Machine. It has increased our production capacity significantlyAmanda K 2024-05-31

The Feminine Napkin Machine is a game-changer for our business. It's efficient, reliable, and produces high-quality products consistentlyRachel W 2024-05-31