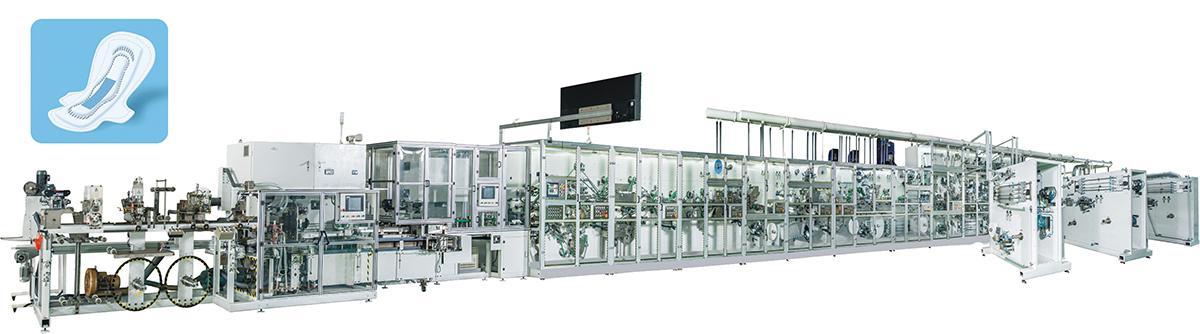

1.Product Structure: Flat(or textile edge)Topsheet,ADL(blue core), Tissue (or airlaid), Cotton core(mix with SAP), Back sheet, Release paper,Pouch film, Fast-easy & package.

2.Product size: 155mm length, to be customized.

3.Program system: Servo driven, intelligent HMl touch screen man-machine interface.

4.Tension system: Tension control with buffer system, automatic web guiding system, to ensure materials stable working at ZERO speed splice.

5.Driven system: Servo drive, digital size change, ensure run synchronously at full process.

6.Safety system: Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

7.Auto Packing system: Auto stacker and packaging machine to be defined by customer need.

8.Web guiding system: Germany BST/USA FIFE.

9.Customized function available

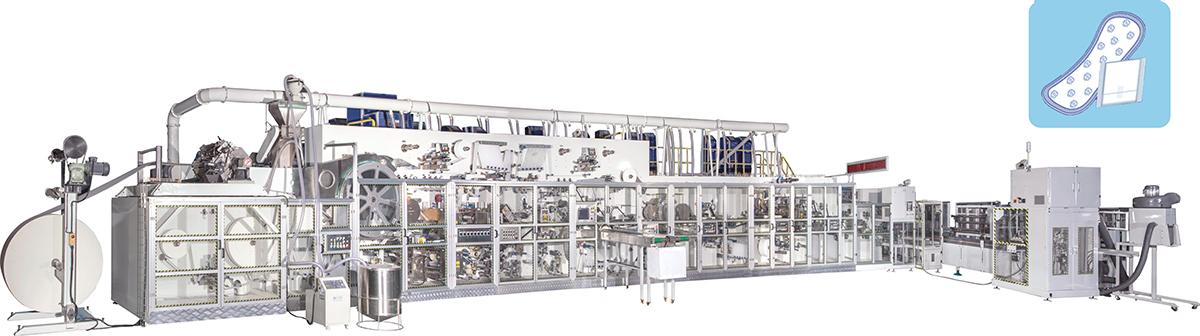

Full Servo Pantyliner Production Line

|

Dimensions(L×W×H8) |

31m*4m*5m |

|

Design Speed: |

1800pcs / per minute |

|

Stable Working Speed: |

1500pcs / per minute |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

50 tons |

Full Servo Pantyliner Production Line+Auto Bagger

| No. | Raw materials |

| 1 | Topsheet NW |

| 2 | Fluff pulp |

| 3 | SAP |

| 4 | Backsheet |

| 5 | Back release paper |

| 6 | Pouch film |

| 7 | Easy tape |

| 8 | Airlaid paper |

| 9 | Construction glue |

| 10 | Position glue |

The sanitary napkin production machine is a modern and advanced technology designed for the manufacturing of high-quality sanitary napkins. The machine is ...

The machine for making sanitary pads is a device designed to manufacture disposable feminine hygiene products. It is equipped with advanced technologies th...

A sanitary napkin making machine is an essential device in the manufacturing industry that produces feminine hygiene products. It is a highly efficient and...

Feminine Napkin Machine has saved us so much time and effort in producing feminine napkins. Couldn't be happier with our purchaseJennifer R 2024-05-31

I love how easy it is to operate the Feminine Napkin Machine. It has increased our production capacity significantlyAmanda K 2024-05-31

The quality of the feminine napkins produced by this Feminine Napkin Machine is unmatched. Our customers have given us great feedback since we made the switchEmily T 2024-05-31

Our customers have noticed the difference in the quality of our feminine napkins since we started using this machine. Highly recommendedMegan H 2024-05-31