Introduction. Growing Demand for High-Speed Production. Automation and Smart Solutions. Sustainable and Eco-Friendly Equipment. Conclusion....

1. Absorbent Core Formation. 2. Elastic Application. 3. Packaging and Quality Control....

Regular Cleaning. Lubrication and Calibration. Scheduled Inspections and Repairs....

1. Improved Efficiency. 2. Enhanced Product Features. 3. Sustainability and Eco-Friendliness....

Introduction. Raw Material Selection. Machine Operation and Maintenance. Quality Control and Testing. Conclusion....

1. Automation and Robotics. 2. Predictive Maintenance. 3. Continuous Process Improvement....

In the use of diaper manufacturing equipment, corresponding maintenance and management should be taken according to the working conditions of the equipment. At ...

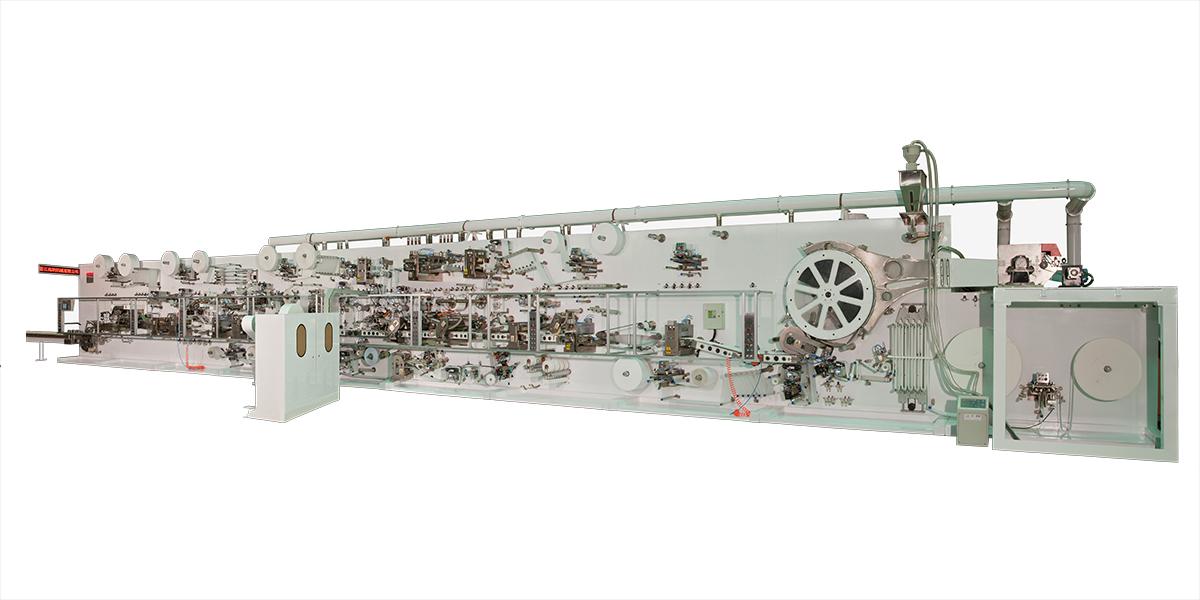

Rejection rate: ≤3%,Efficiency: ≥85%, Packaging system: Auto stacker to be defined by customer need (dual push dual exit), the stacking range: 16-36pcs/pack adjustable. Web guiding sy...

1. estrutura do produto: Tecido superior e inferior (ou airlaid), núcleo de algodão (misturado com SAP), não tecido hidrofílico da folha superior, não tecido ADL, manguito de vazam...

1.automatic adult diaper making production line Program System Servo driven, intelligent HMI touch screen man-machine interface 2.Tension System Tension control with buffer system, aut...

This is Sanitary Napkin Manufacturing Machine in Pakistan.It can produce 2 size of : 290mm and 320mm. The stable speed is 1000 ppm. The servo motor brand is Misubushi from Japan ,and w...

This is Disposable Bed Pads Machine in Czech Republic. The machine stable speed is 250meter/min.The Disposable Bed Pads is a disposable hygiene product, which made up of nonwoven, ti...