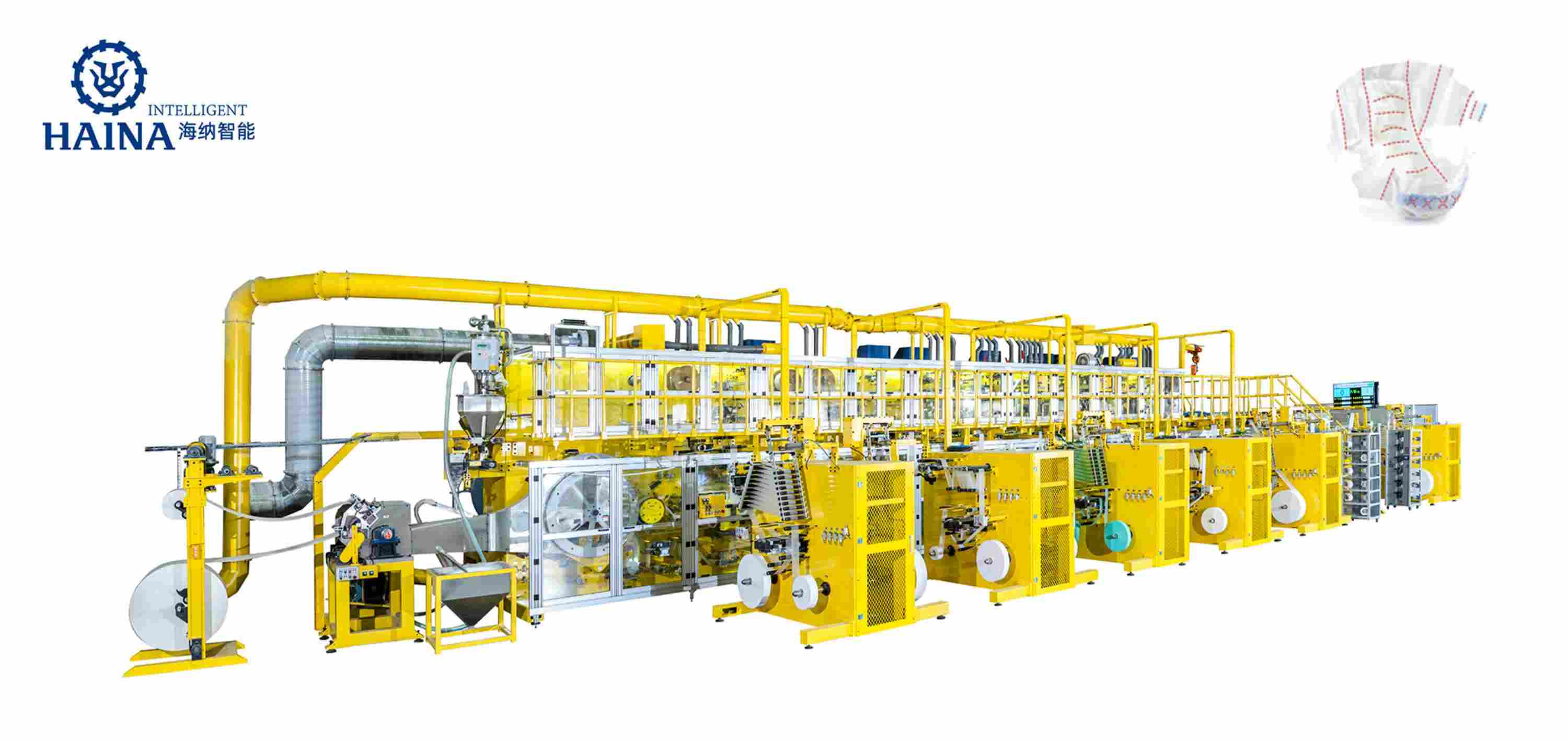

1.Product structure: Upper & lower tissue (or airlaid ), Cotton core (mix with SAP), Topsheet hydrophilic nonwoven, ADL nonwoven, Leak cuff

hydrophobic nonwoven, Back sheet, Waist nonwoven, Printed cartoon tissue, Waist elastic, Easy tape.

2.Product size: 4 sizes (M, L, XL, XXL), to be customized.

3.Program system: Servo driven, intelligent HMl touch screen man-machine interface.

4.Tension system: Tension control with buffer system, automatic web guiding system, to ensure materials stable working at ZERO speed splice.

5.Driven system: Servo drive, digital size change, ensure run synchronously at full process.

6.Safety system: Safety guard for operating side, emergency stop switch, security identifier, safety pull wire at driven side.

7.Packaging system: Auto stacker to be defined by customer need (dual push dual exit), the stacking range: 16-36pcs/pack adjustable.

8.Web guiding system: Germany BST/USA FIFE.

9.Customized function available

|

Dimensions(L×W×H8) |

34m*2.2m*3.8m |

|

Design Speed: |

1000 pcs per minute |

|

Stable Working Speed: |

900 pcs per minute |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

350-550KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

90 tons |

Baby Pull-ups Diaper Manufacturing Machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Frontal tape |

| 12 | NW for S cut |

| 13 | Hook for S cut |

| 14 | Glue for S cut |

| 15 | NW for big waistband |

| 16 | Elastic for big waistband |

| 17 | Construction glue |

| 18 | Elastic glue |

| 19 | Wetness indicator glue |

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

1. T-Shape Ear Type Baby Diaper Machine Program System Servo driven, intelligent HMI touch screen man-machine interface 2. Driven System Servo drive, digital size change, ensure run synchronously...

This is full servo adult diaper making machine for the customer from Russia. The machine stable speed is 260PPM. The customer purchased this machine from H...

Diaper Manufacturing Machine For Sale. This machine can produce four sizes of the baby diaper, machine with Nordson glue applicator and without stacker....

The Baby Diaper machine technical support provided by the manufacturer has been excellent, ensuring that our production runs smoothly without any hiccups.amy 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30

The reliability of the Baby Diaper Machine has given us peace of mind. We can fulfill orders on time without worrying about breakdowns or delays.Henry 2024-05-30

The Baby Diaper machine's flexibility allows us to customize diaper designs according to market trends, giving us a competitive edge. Our customers appreciate the variety.Carter 2024-05-30