Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-11

At present, China has made considerable progress in electronic technology and automation technology. The extensive application of best nappy machine in machinery manufacturing industry is the most intuitive embodiment of this progress. For the mechanical manufacturing industry that applies sanitary napkin equipment, although this application can bring good benefits, the problem that sanitary napkin equipment is prone to failure must also be paid attention to. This paper studies the fault diagnosis and maintenance measures of napies machine.

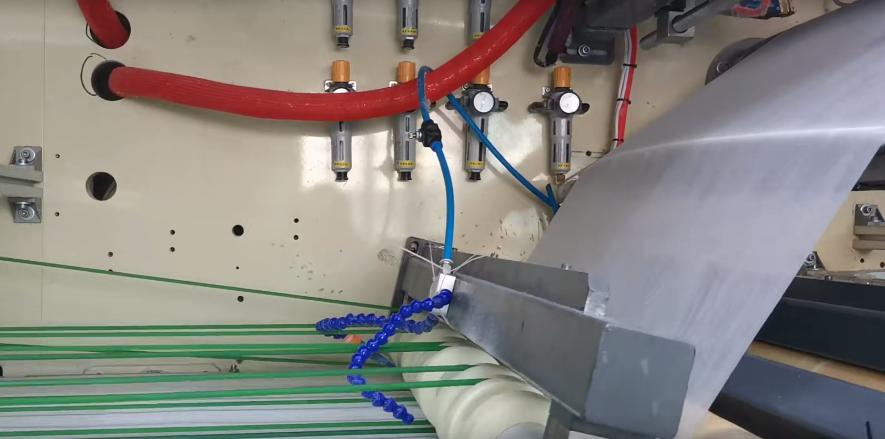

For the best nappy machine, it can automatically complete the processing of relevant parts and products through the control signal sent by the pre compiled program. This function enables the sanitary napkin equipment to complete the processing of complex, precise, small batch and multi variety parts and products without the support of a large number of human resources, This feature also makes sanitary napkin equipment a typical mechatronic product. Compared with traditional machines, sanitary napkin equipment has a series of advantages, such as high flexibility, high processing precision, stable and reliable processing quality, high productivity and improved working conditions. These advantages also make sanitary napkin equipment effectively promote the development of China's machinery manufacturing industry.

Common best nappy machine faults include power supply, short circuit, controller, etc.

2.1 power failure

For sanitary napkin equipment, the power supply is the basic premise for its normal operation. If this premise fails, the sanitary napkin equipment can not work normally, and it is also prone to the loss of database information. In serious cases, it can even cause the machine to stop. This shows the severity of the power supply failure of sanitary napkin equipment. In the diagnosis of sanitary napkin equipment with power failure, the specific operation of this diagnosis is to check whether the power supply of sanitary napkin equipment is well grounded, and whether there is running leakage and series power.

2.2 short circuit fault

In addition to power failure, short circuit fault is also a common fault form in the operation of sanitary napkin equipment. Behaviors such as incorrect two potential points, direct contact, connecting conductors with very small resistance, and connecting lines that do not need to be connected can cause short circuit fault of sanitary napkin equipment. If the sanitary napkin equipment has a short-circuit fault, its own operation control system is prone to confusion, which eventually leads to the system out of control and shutdown for maintenance. For sanitary napkin equipment, insulation aging, moisture damage and subsequent chain failure of components can cause short-circuit fault of sanitary napkin equipment, and relevant staff mainly start from these fields to diagnose short-circuit fault of sanitary napkin equipment.

2.3 controller failure

For the best nappy machine, the controller fault is also a common fault. This fault is mainly caused by the line contact problem caused by electric shock. A large number of relays used in the sanitary napkin equipment system are the main factors inducing the controller fault. According to the research of relevant industry authoritative organizations, the more relays in the sanitary napkin equipment system, the more controller faults are likely to occur in the relevant sanitary napkin equipment, It can be seen that the succession of sanitary napkin equipment system is the key to the diagnosis of this fault.

In addition to the above specific machine and equipment failures, the maintenance information tracking method is also a machine and equipment failure resolution measure that can be adopted by relevant staff. This method can provide a reference for future machine and equipment failure resolution on the premise of combining the electronic equipment maintenance archives, which has a long-term significance for the smooth operation of machine and equipment.