The Pampers making machine is a top-of-the-line piece of equipment designed to efficiently manufacture high-quality diapers. Its advanced features include automatic feeding, cutting, and folding, which streamline the production process and increase output rates.

One key advantage of the Pampers making machine is that it is highly customizable, allowing for the production of a wide range of diaper sizes and styles. Additionally, the machine is equipped with sensors and controls that ensure consistent product quality and help to minimize waste.

Another major benefit of the Pampers making machine is its reliability and durability. Built with high-quality materials and advanced manufacturing techniques, this machine is designed to withstand constant use and long-term wear and tear, making it a wise investment for any manufacturer.

Overall, the Pampers making machine is an essential tool for any business looking to enter the competitive and lucrative market for disposable diapers. Its advanced features, customization options, and robust construction make it a top choice for manufacturers worldwide.

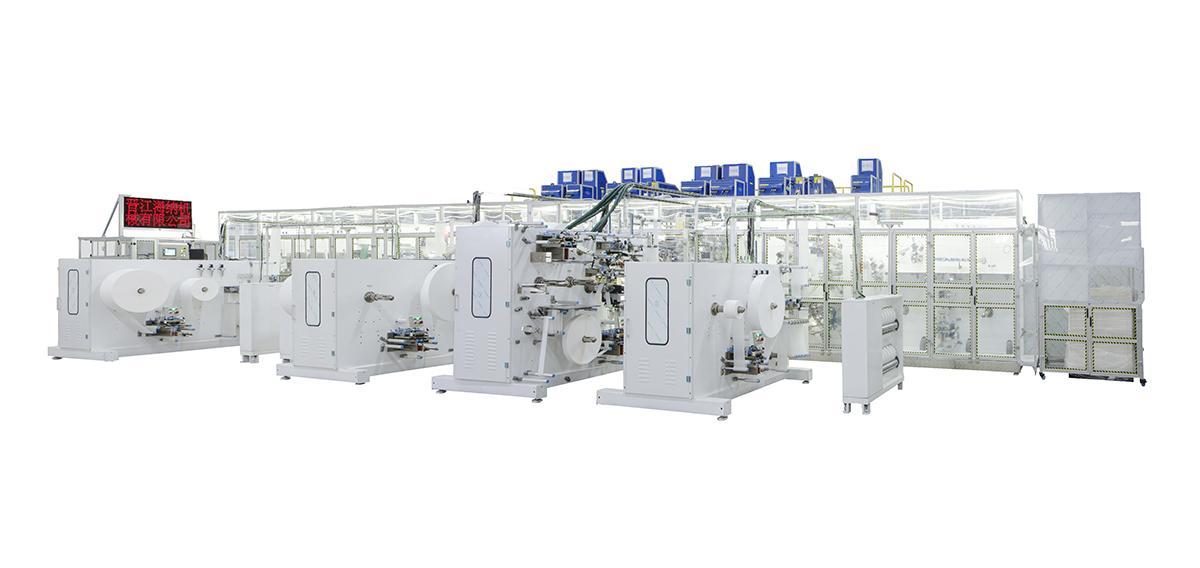

Baby Pampers Making MachineProduct Description:The Baby Pampers Making Machine is a state-of-the-art automated production system designed specifically for the manufacturing of baby diapers. The machine incorporates advanced technologies and features to ensure high-quality output and efficient production. It is built with precision engineering and industry-leading materials to meet the demands of modern diaper manufacturing.

baby pampers making machine Technical Features:

1. High-Speed Production: The machine is capable of producing diapers at a high production rate, ensuring maximum productivity.

2. Adjustable Sizes: With customizable settings, the machine can produce diapers in different sizes, catering to the diverse needs of infants.

3. Quality Control System: Equipped with a robust quality control system, the machine ensures that each diaper meets the required standards for baby hygiene and comfort.

4. User-Friendly Interface: The machine features an intuitive interface, allowing operators to control and monitor the production process effortlessly.

5. Efficient Material Usage: The machine optimizes material consumption, minimizing waste and reducing production costs.

baby pampers making machine Product Application:

The Baby Pampers Making Machine is primarily used in large-scale manufacturing facilities dedicated to the production of baby diapers. It is suitable for both established diaper brands and emerging companies looking to enter the market. The machine offers a reliable and cost-effective solution for producing high-quality diapers that cater to the delicate needs of babies.

baby pampers making machine Main Functions:

1. Absorbent Core Formation: The machine efficiently forms the absorbent core of the diapers, ensuring optimal absorption and leakage protection.

2. Elastic Waistband Application: It precisely applies the elastic waistband, providing a secure and comfortable fit for the baby.

3. Frontal Tape Attachment: The machine attaches the frontal tapes with accuracy, ensuring ease of use and proper fastening.

4. Shape Molding: It molds the diaper into the desired shape, creating a snug fit that allows freedom of movement for the baby.

5. Packaging: The machine can also be configured for automated packaging, reducing manual labor and increasing overall production efficiency.

baby pampers making machine Precautions:

1. Regular Maintenance: To ensure consistent performance, regular maintenance of the machine is essential.

2. Safety Protocol: Operators should strictly adhere to safety guidelines and wear appropriate protective equipment while operating the machine.

3. Proper Training: Operators should receive comprehensive training on machine operation and maintenance to maximize productivity and minimize errors.

4. Quality Control Checks: Regular quality control checks should be conducted to verify the output meets the required standards.

5. Material Compatibility: Only approved materials and components should be used in the machine to avoid any adverse effects on the quality of the diapers.

In conclusion, the Baby Pampers Making Machine is a reliable and advanced solution for high-quality baby diaper manufacturing. With its cutting-edge technology, adjustable settings, and efficient production capabilities, it caters to the diverse needs of both established and emerging diaper companies. Operators should follow proper safety protocols, conduct regular maintenance, and ensure the use of approved materials to achieve optimal performance and output.

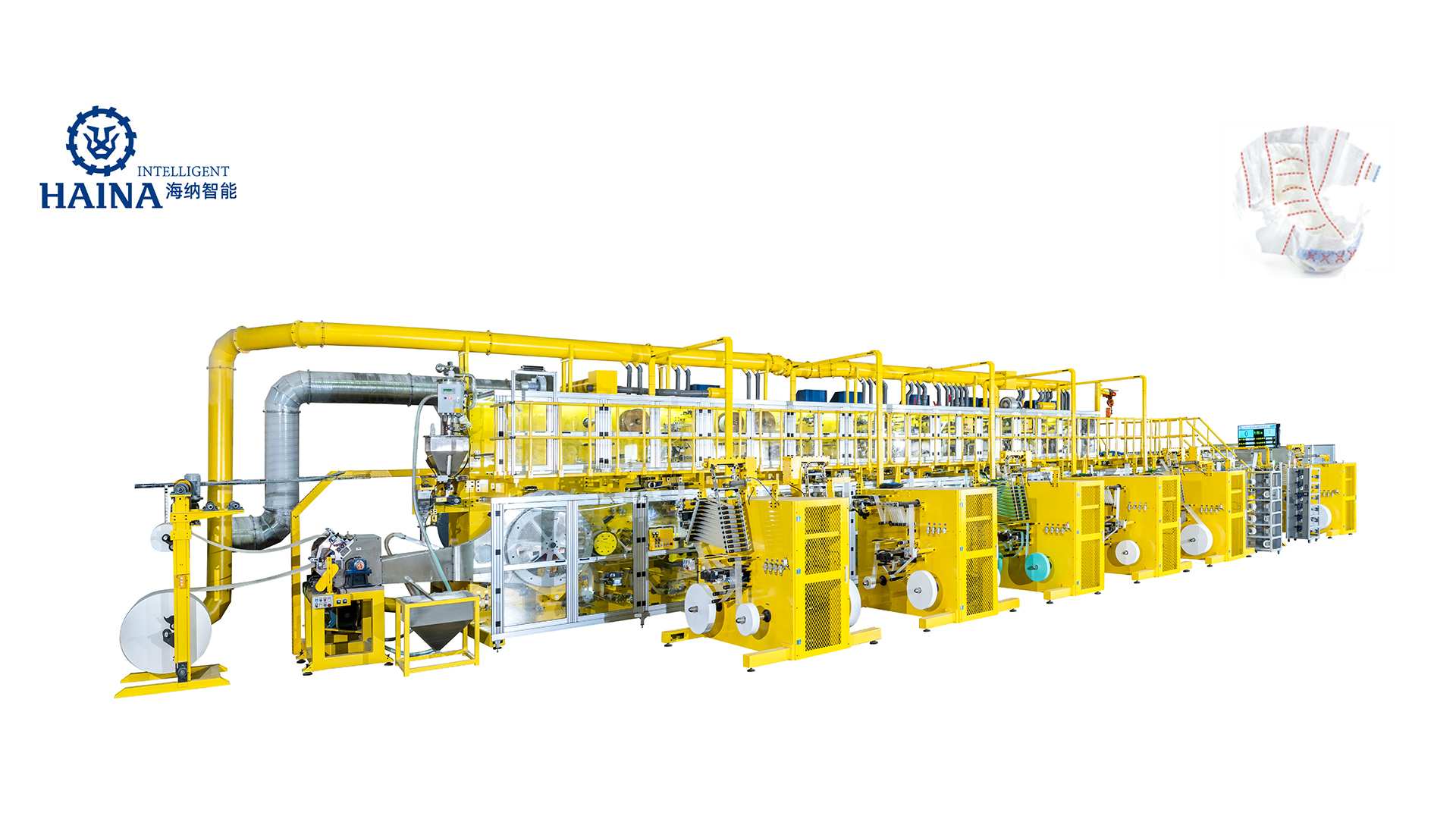

Pull-ups Baby Diaper Machine

|

Dimensions(L×W×H8) |

32m*1m*4m |

|

Design Speed: |

600ppm |

|

Stable Working Speed: |

500ppm |

|

Rejection Rate: |

≤3% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

320KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

80 tons |

LK600-baby pampers making machine

| No. | Raw materials |

| 1 | Hydrophilic NW (Topsheet) |

| 2 | Hydrophobic NW (Legcuff) |

| 3 | Elastic for Legcuff |

| 4 | ADL |

| 5 | Fluff pulp |

| 6 | SAP |

| 7 | Upper tissue/NW |

| 8 | Lower tissue/NW |

| 9 | Pe film |

| 10 | NW for laminating |

| 11 | Waist inner NW |

| 12 | Waist outer NW |

| 13 | Elastic for waist |

| 14 | Construction glue |

| 15 | Elastic glue |

| 16 | Wetness indicator glue |

Overall size: 30mx6mx3.8m(for reference only), Product structure: Upper & lower tissue, Cotton core(mix with SAP),ADL, Backsheet, Frontal tape, Topsheet hydrophilic nonwoven, Leg cuff hydrophobic ...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

The pictures shows our adult pant machine in customer’ssite, this machine can produce M/L/XL three sizes,stable working speed300pcs/min for M size. Compar...

This is Sanitary Napkin Making Machinewhich designed for Middle Asia customer. It can produce 3 size of : 250mm,280mm,and 320mm. The stable speed is 700-9...

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30

Our operational costs have decreased significantly, thanks to the efficiency of the Baby Diaper Machine. It's a cost-effective solution for any diaper manufacturer.Matthew 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30

We've received positive feedback from parents who love the softness and snug fit of the diapers produced by this Baby Diaper machine. It's a win-win for everyone.Jack 2024-05-30