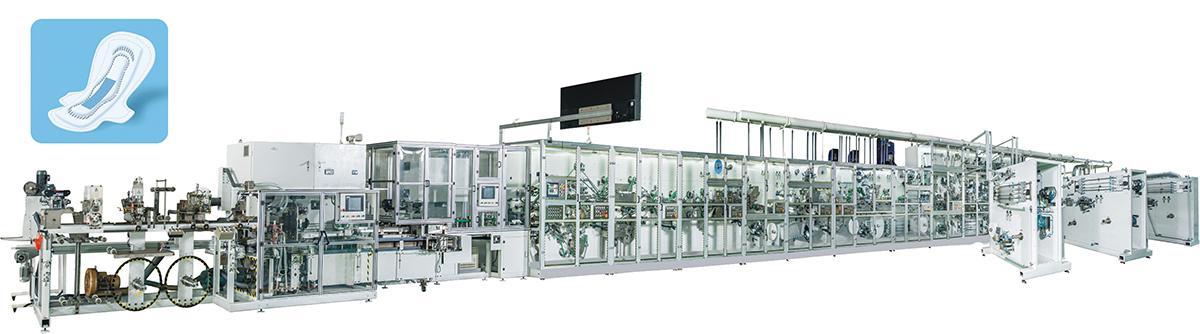

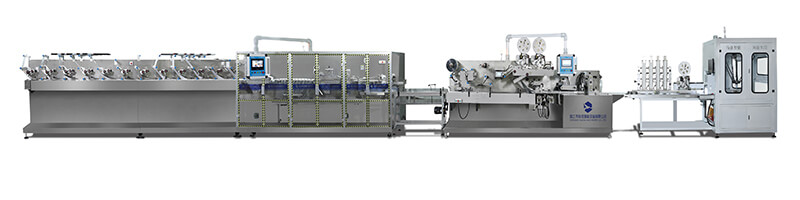

In the case of semi-automatic baby diaper production increasingly pursuing fine management and information operation, the quality and effect of infant diaper machine installation, the influence on enterprise semi-automatic baby diaper production is increasing. In order to ensure the continuity and stability of enterprise production and the smooth realization of economic benefits, environmental benefits and safety benefits, enterprises need to continuously strengthen the research of infant diaper machine installation process.

1. Enhance the importance of infant diaper machine installation process

The infant diaper machine installation process is one of the core technical contents of the enterprise production. In order to ensure that baby diaper machine installation is not limited by others, enterprises should pay enough attention to baby diaper machine installation process research and innovation, and gradually improve their own mechanical equipment installation capabilities. On the one hand, enterprises should treat the equipment installation process correctly, out of the simple cost standard-led equipment installation process development concept. In fact, equipment installation is not simply an act of equipment installation, but an important link in the application of the entire semi-automatic baby diaper production technology. Enterprises should examine, analyze and grasp the importance of machinery and equipment installation process from the perspective of the production chain in order to change the lagging concept in equipment installation. On the other hand, enterprises should clarify the main content of baby diaper machine installation. Equipment installation includes not only the installation operations at the site of machinery and equipment installation, but also the environmental investigation and analysis of requirements before the installation of machinery and equipment, as well as the commissioning and operation monitoring after the end of the installation. Only by ensuring the effective implementation of the whole process can we guarantee the effective equipment installation operation.

2. Strengthen the infant diaper machine installation process improvement

The new iteration of machinery and equipment makes the installation process of infant diaper machine should also keep continuous improvement. In order to ensure that the newly introduced machinery and equipment can be installed and used correctly, enterprises should strengthen the continuous improvement of machinery and equipment installation process. First, to improve the machinery and equipment assembly technology. The assembly technology of the enterprise will be different because of the different types of mechanical facilities, therefore, after making decisions on the use of machinery and equipment, the enterprise should organize multi-departmental and multi-faceted experts to conduct in-depth and detailed discussions on the assembly technology of machinery and equipment installation, and finally determine the scientific and reasonable technical assembly method to ensure the scientific and effective installation of machinery and equipment. Second, to focus on the quality control of mechanical welding points. Mechanical welding point is the later use of machinery and equipment often appear in the process of problems. In the process of machinery and equipment installation, enterprises should make a careful analysis and grasp of the internal and external defects in the welding of machinery and equipment, as well as the size of the welding and other information to ensure the effectiveness of welding operations. For example, for external welding points such as pressure pits and edge biting problems, to ensure the smoothness and smoothness of the machine surface by carrying out a careful inspection of the machine surface and processing the welded points.

3. Pay attention to the feedback processing of infant diaper machine installation process

The completion of the installation of infant diaper machine does not mean the end of the whole installation work. Enterprises should set the corresponding observation period according to the type of machinery and equipment, and monitor and analyze the operation of the newly installed machinery and equipment to ensure the stability and continuity of machinery and equipment operation. In the process of monitoring machinery and equipment, in addition to arranging special personnel responsible for monitoring, enterprises should also pay attention to the collection, analysis, feedback and resolution of problems that arise in monitoring, so that problems in the operation of machinery and equipment can be grasped and solved in a timely manner. For example, enterprises can monitor the list of technical personnel to master the daily operation of machinery and equipment related data information, to data information to accurately grasp the operation of machinery and equipment. For the problems that appear in the operation of machinery and equipment, enterprises should adopt the responsibility system, the technical personnel who found the problem as the first responsible person, responsible for tracking the follow-up of the problem, to ensure that the problems found in the shortest possible time to be solved.

For the current infant diaper machine installation in a series of problems, enterprises should strictly carry out machinery and equipment material inventory and quality inspection work, training professional machinery and equipment installation team, enhance baby diaper machine installation process importance, strengthen the improvement of machinery and equipment installation process, pay attention to the feedback of the problems in the process of machinery and equipment installation Strategies such as processing to optimize the solution, in order to promote the continuous improvement of the enterprise equipment installation process.