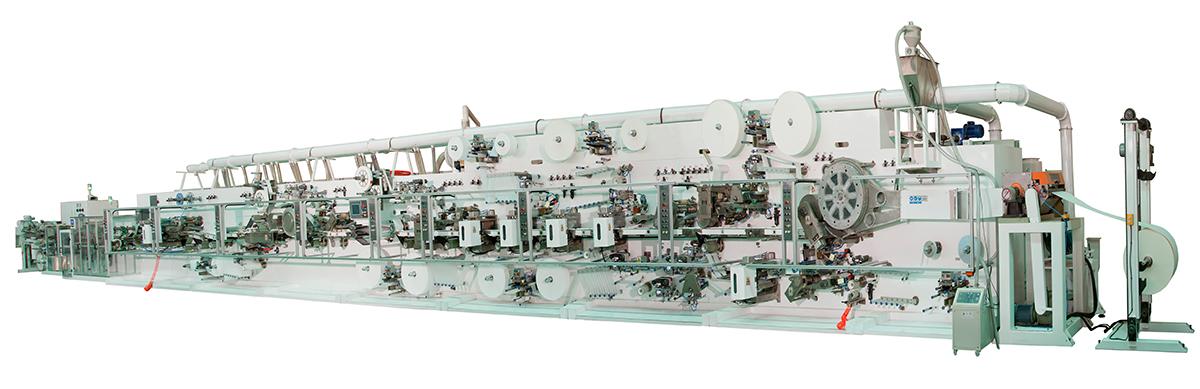

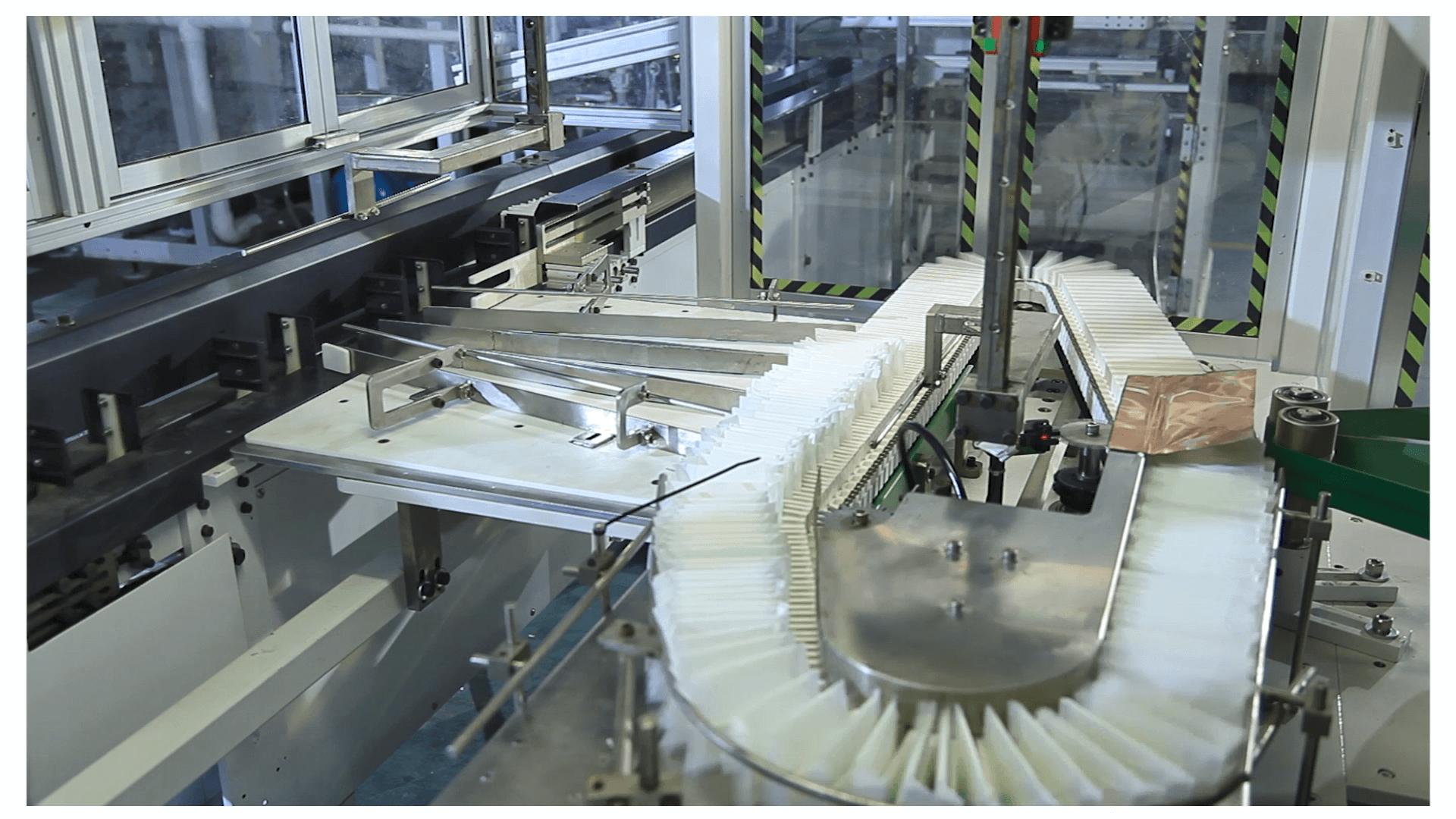

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-09

Lady diaper manufacturing machine The loss of working ability of machinery is called failure, and the loss of specified working ability of machine parts is called failure. Mechanical failure and component failure are inseparable. The failure caused by the failure of the parts due to the deformation, fracture, corrosion, etc. of the parts caused by normal wear or physical and chemical changes, such failures are also called natural failures. The lady diaper manufacturing equipment's parts assembly process is an important link in determining the quality of mechanical repairs. A lady diaper manufacturing equipment with excellent quality is also essential for cleaning.

(1) The assembled parts themselves must meet the specified technical requirements, and any unqualified parts cannot be assembled. This part must be strictly inspected before assembly.

(2) The correct matching method must be selected to meet the requirements of matching accuracy. A large amount of work in mechanical maintenance is to restore the matching accuracy of mutual cooperation, and methods such as selection, repair, and adjustment can be used to meet this requirement. The effect of thermal expansion should be considered for the fit clearance. For fittings composed of materials with different expansion coefficients, when the ambient temperature during the assembly process is quite different from the working temperature, the gap change should be compensated.

(3) Analyze and check the accuracy of the assembly dimension chain, and meet the accuracy requirements through matching and adjustment.

(4) The principle of handling the assembly sequence of the parts is: first inside and then outside, first difficult and then easy, first precision and then general.

(5) Select the appropriate assembly method and assembly equipment and tools.

(6) Pay attention to the cleaning and lubrication of parts. Assembly parts must first be thoroughly cleaned and a lubricant suitable for the job should be applied to the relatively moving surfaces.

(7) Pay attention to the sealing during assembly to prevent "three leaks". To use the specified sealing structure and sealing material, can not use arbitrary substitutes. Pay attention to the quality and cleanliness of the sealing surface. Pay attention to the assembly method and assembly tightness of the seal, and the static seal can be sealed with an appropriate sealant.

(8) Pay attention to the assembly requirements of the locking device and comply with safety regulations.

(9) Pay attention to the quality inspection of the intermediate links of assembly.

Remove oil stains; oil stains are the attachments of grease, dust, rust, etc., which do not dissolve into water, but into organic agents. In addition to mechanical methods, chemical methods or electrochemical methods can also be used.

(1) Chemical degreasing method:

a. Organic solvent degreasing: Commonly used organic solvents are gasoline, kerosene, diesel oil, acetone, etc.

b. Alkaline solution for oil removal: such as caustic soda, sodium carbonate, sodium silicate, sodium phosphate, etc. Raising the temperature of the solution and stirring during cleaning can speed up the degreasing effect. Generally, it can be heated to about 80 °C. After washing, it should be rinsed with hot water and dried with compressed air.

(2) Electrochemical degreasing method: The method of using the mechanical stirring and peeling action of the bubbles generated by the two electrodes during electrolysis to remove the oil from the surface of the parts is called the electrochemical degreasing method. The method has the advantages of high speed, high efficiency, and thorough oil removal.

Lady diaper manufacturing machine. Maintenance problems will become more and more scientific, reasonable and efficient, making greater progress in daily repair and maintenance of technical problems by engineers, and gradually improving the economic manufacturing effect of related factories and enterprises.