Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-04-07

Maintenance measures are the main focus of the production and manufacture of best sanitary napkins machine. In order to improve its work efficiency and prolong its service life, we should do a good job in the maintenance and management of best sanitary napkins machine. The specific maintenance steps are as follows:

(1) All oiling points of the best sanitary napkins machine production line equipment must be regularly filled with engine oil, lubricating oil or grease according to the requirements of their parts.

(2) The seals (wearing parts) must be checked every day, and if they are damaged, they must be replaced immediately.

(3) Check the protective board of the chamber every day, and replace it immediately if it is damaged.

(4) Inspect the protective plate, blade, impeller, directional sleeve and shot dividing wheel of the shot blasting device twice every shift, and replace them immediately in case of damage.

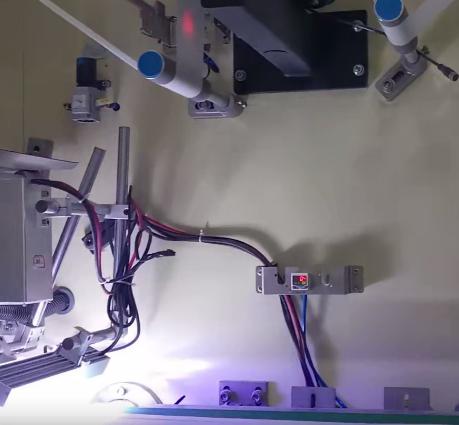

(5) The electrical system should be checked again. Check whether the main bearings are well lubricated and whether there is high temperature or abnormal sound.

(6) All transmission parts shall be inspected twice a week. Inspect the working status of electric control cabinet, electric control components on the console, motors, solenoid valves, etc. at any time.

(7) The operator should check the cleaning effect at any time. If there is any abnormality, he should stop the machine immediately and check the equipment as a whole.

(1) Raw materials must be stacked neatly and orderly.

(2) All maintenance, spare parts and other tools should be stored in the toolbox.

(3) It is strictly prohibited to place inflammable and explosive materials on the best sanitary napkins machine.

(4) The parts used must be kept clean, and only water and alcohol can be used to scrub rubber parts, plastic parts and paint parts.

(5) Machine to make sanitary pads all parts must be oiled regularly to prevent rust.

(6) Before opening the sanitary napkins machine, the product contact surface on the production line should be cleaned in time to ensure that it is clean and free of debris.

(7) The back transmission room cleans the body surface, spur gear box, differential motor and synchronous wheel.

(8) The working area around the equipment shall be kept clean and free of sundries; The external surface of the machine platform shall be cleaned, and the passage and the lower part of the machine platform shall be cleaned, and the windowsill wall foot shall be wiped.

(9) The electric control device of the best sanitary napkins machine should be kept clean and complete.

(10) Regularly check the lubrication condition of the chain and add lubricating oil to the insufficient ones.

(11) Carefully check whether the main bearings are well lubricated.

(12) If the equipment makes abnormal noise during the operation of the production line, it must be shut down in time for adjustment.

(13) The working conditions of all important parts of the equipment should be done well. If there is any abnormality, the machine should be shut down immediately for maintenance.

In order to save costs, extend the service life of the best sanitary napkins machine and bring more benefits to our production, the use, maintenance and management of the best sanitary napkins machine is a compulsory course for non-woven fabric manufacturers, which needs to be paid attention to.