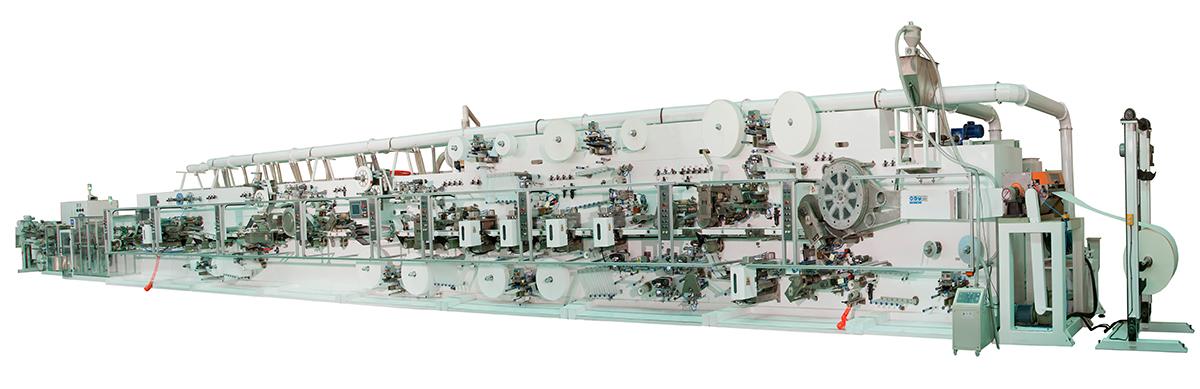

Author:Haina Machinery Factory FROM:Diaper Machinery Manufacturer TIME:2023-03-10

menstrual diaper machine's various bad loss situations will have a direct impact on the equipment. Because loss means waste and loss in English, we call menstrual diaper machine various causes of bad situations such as downtime, failure, damage, etc., as loss items.

These loss items include: failure loss; mold replacement and adjustment loss; idle operation and suspension loss; deceleration loss; quality defect and rework; start-up loss, etc. The purpose of reducing equipment damage is to increase its comprehensive utilization rate, to ensure that machinery does not produce defective products, and to improve production efficiency.

menstrual diaper equipment Downtime/loss refers to lost time and lost volume due to production defects. Sudden, significant equipment failures due to occasional failures are usually obvious and easy to correct; frequent, or chronic, minor failures are often overlooked or missed. Since accidental failures account for a large proportion of the overall loss, many businesses spend a lot of time finding and avoiding such failures. However, it is difficult to eliminate these occasional failures. Therefore, it is necessary to carry out research to improve its reliability. To maximize the mechanical efficiency, the failure must be reduced to zero. Therefore, it is first necessary to change the traditional view that failure is unavoidable in fault maintenance.

menstrual diaper equipment. The loss of refitting and debugging is the damage caused by downtime and waste products caused by refitting and debugging, which generally occurs when the production of one product is completed, and the refitting and debugging are carried out due to the production of another product. In order to realize the replacement within a period of time (less than 10 minutes), it is possible to clearly distinguish the replacement time (the operation is completed after the machine is stopped) and the replacement time (the operation is completed while the machine is running), reducing the replacement time and reducing the loss of the entire replacement time.

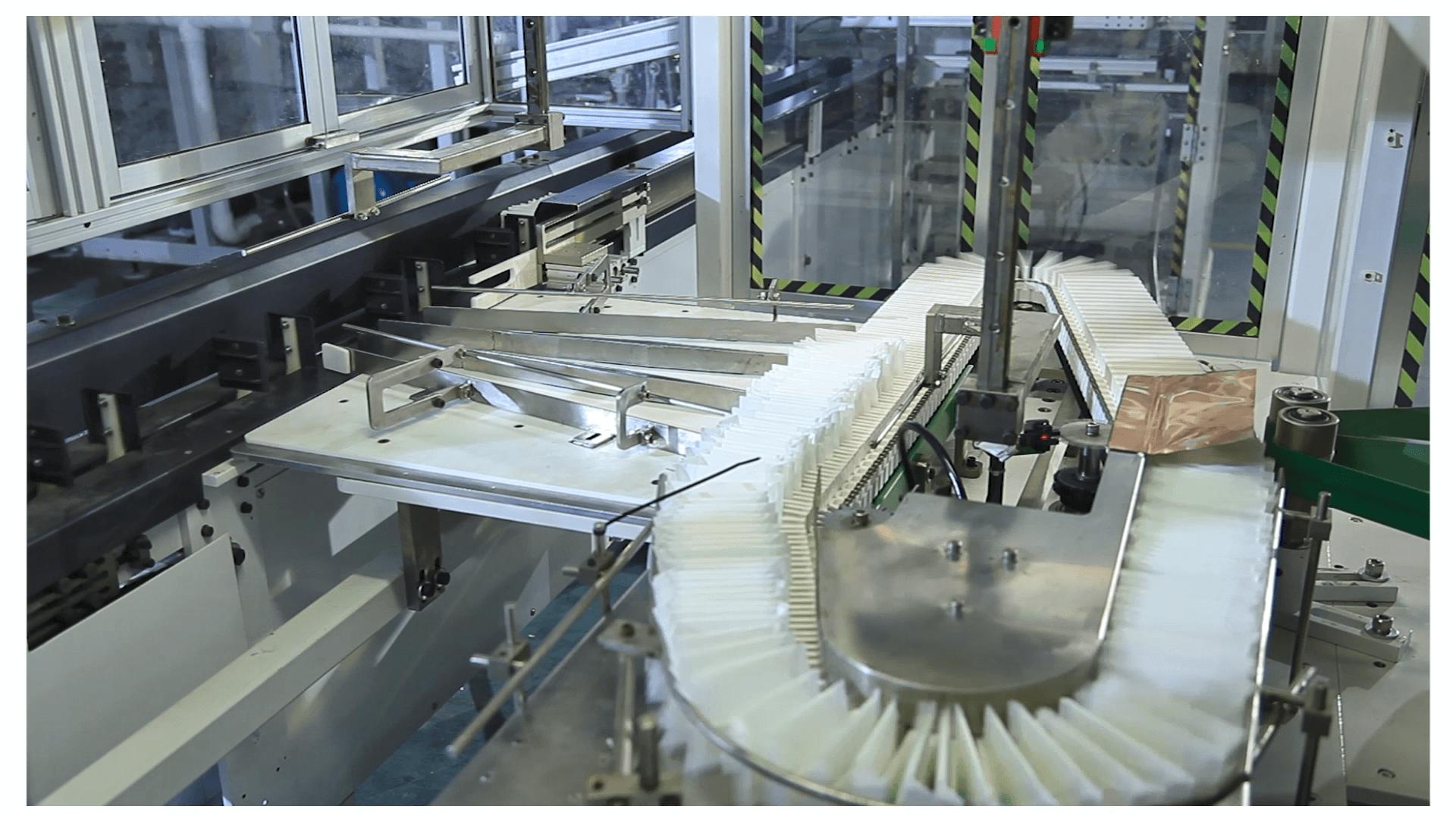

Idle and pause losses refer to stalls due to misuse or short pauses when the machine is idle. For example, some workpieces blocked the top of the chute, causing the equipment to be idle; the sensor alarmed and the machine was shut down due to the production of defective products. Obviously, this kind of pause is different from a breakdown, because removing the blocked workpiece and restarting the equipment is Production can be resumed.

Deceleration loss is the difference between the design speed and the actual speed. The speed loss creates a big obstacle to the performance of the equipment and should be carefully studied to eliminate the difference between the design speed and the actual speed. There are various reasons why the actual speed is lower than the design speed or ideal speed, such as mechanical problems and quality defects, historical problems or overloading. Often, prudently increasing operator speed helps resolve problems by uncovering potential flaws.

Quality defects and rework refer to the quality defects and rework in the production process caused by failures. Usually, accidental defects can be easily eliminated by resetting the equipment to the normal state. These defects include a sudden increase in the number of defects or other obvious phenomena. The causes of chronic defects are difficult to find and are often missed or ignored. Defects that require rework are also chronic injuries.

Start-up losses are losses incurred during the initial stages of production (from equipment start-up to stable production). The amount of these damages varies depending on the stability of the process state, the maintenance level of equipment fixtures and molds, the proficiency of operating skills, etc. This loss is large and potential. In actual production, it is usually undiscriminated that the production loss is inevitable, so it is rarely eliminated.

Paying attention to the bad conditions of the machine can not only avoid menstrual diaper machine failures, reduce the damage caused by production stagnation, but also reduce the wear and tear of machine tool parts, reduce maintenance costs, and save a lot of costs for the factory in one year. Promote the continuous progress of enterprises in the direction of high yield and high quality.