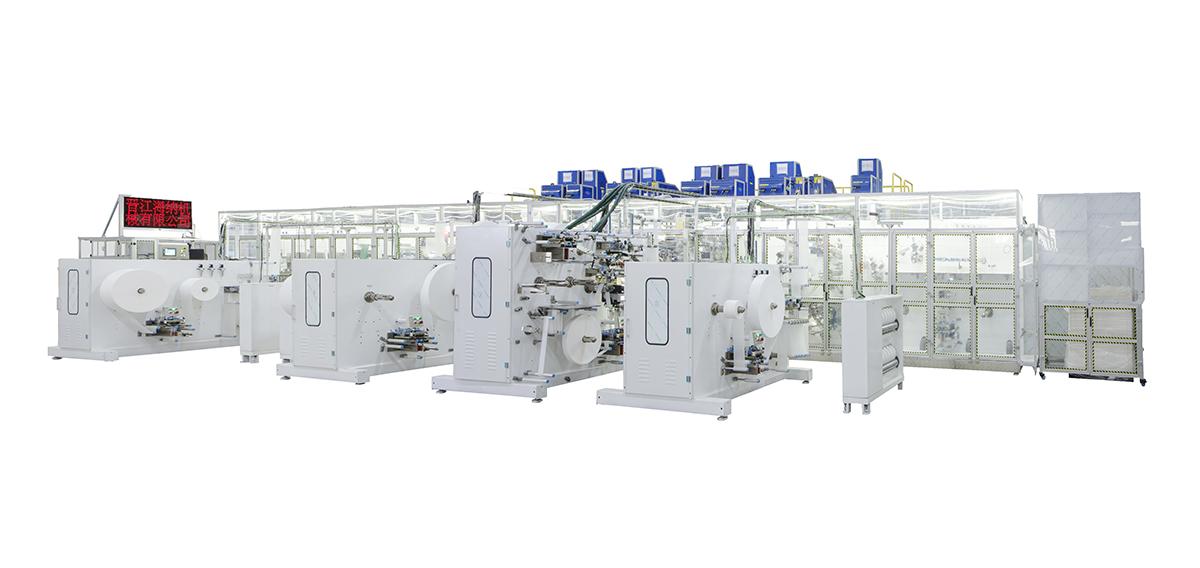

This fully-automatic baby diaper machine saves time and human resources by reducing the need for manual labor and manufacturing high-quality products. It is an ideal choice for diaper manufacturers who want to produce high-quality, cost-effective, and environmentally-friendly baby diapers.

|

Dimensions(L×W×H8) |

30m*6m*3.8m |

|

Design Speed: |

500ppm |

|

Stable Working Speed: |

400-450ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

75 tons |

Strengthen the ability and quality of the operators of Baby Diaper Machine

1. The technical level of maintenance personnel is an important factor affecting the maintenance efficiency of Baby Diaper Machine.

Having a high-quality workforce is the basis for promoting the continuous improvement of equipment maintenance efficiency.

2. The improvement of the technical level of the maintenance personnel of baby diaper Production Line can be carried out in the following ways:

First, take a combination of bringing in and sending out. Second, through internal training and learning, cultivate equipment management, use and maintenance personnel, and use business time to hold equipment use training activities to continuously improve the technical level of personnel. Third, strengthen the improvement of the employee assessment mechanism, increase the assessment of the survival of the fittest, stimulate the enthusiasm of the employees, and also promote the continuous learning of the employees, providing necessary guarantees for the use and maintenance of equipment.

|

No. |

Raw materials |

|

1 |

Hydrophilic NW (Topsheet) |

|

2 |

Hydrophobic NW (Legcuff) |

|

3 |

Elastic for Legcuff |

|

4 |

ADL |

|

5 |

Fluff pulp |

|

6 |

SAP |

|

7 |

Upper tissue/NW |

|

8 |

Lower tissue/NW |

|

9 |

Pe film |

|

10 |

NW for laminating |

|

11 |

Frontal tape |

|

12 |

Elastic NW for big ear |

|

13 |

NW for small ear |

|

14 |

Magic side tape |

|

15 |

Construction glue |

|

16 |

Elastic glue |

|

17 |

Wetness indicator glue |

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, emergency s...

The fully automatic baby diaper machine is a high-tech and efficient piece of equipment used to manufacture high-quality disposable baby diapers. This machine is designed to be fully automated, w...

Disposable Nappies Making Machine in Cameroon, this machine can produce four sizes of baby diaper, S/M/L/XL, this machine without stacker and with Chinese...

This is a Haina baby Pants machine designed forPhilippines customers. It can produce four sizes of M / L, with a stable production speed of 700 pieces / m...

The Baby Diaper machine technical support provided by the manufacturer has been excellent, ensuring that our production runs smoothly without any hiccups.amy 2024-05-30

The Baby Diaper Machine efficient, reliable, and produces high-quality diapers consistentlyjone 2024-05-30

This Baby Diaper Machine has streamlined our manufacturing process and allowed us to deliver diapers that exceed our customers' expectations in terms of comfort and absorbencyMason 2024-05-30

We've seen a significant improvement in production output and product quality since we started using the Baby Diaper Machine. Our customers love the result!Liam 2024-05-30