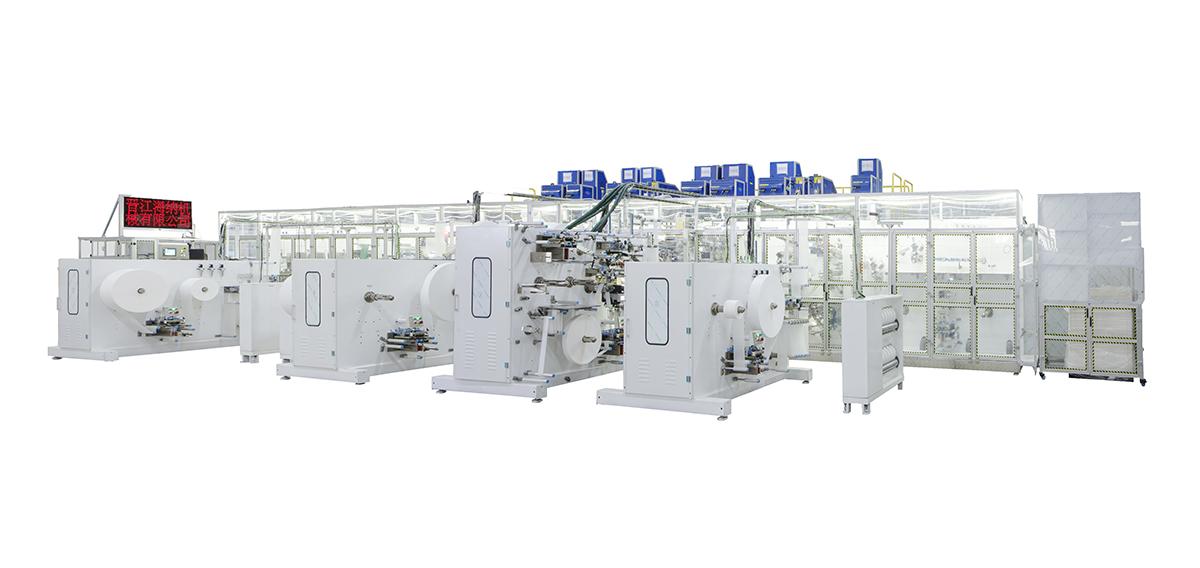

7. T-Shape Ear Type Baby Diaper Machine Customized Function Available

|

Dimensions(L×W×H8) |

30m*6m*3.8m |

|

Design Speed: |

500ppm |

|

Stable Working Speed: |

400-450ppm |

|

Rejection Rate: |

≤4% |

|

Efficiency: |

≥85% |

|

Power Source: |

380V,50HZ |

|

Machine Capacity: |

290KW |

|

Air Pressure: |

0.6-0.8Mpa |

|

Machine Weight: |

75 tons |

T-Shape Ear Type Baby Diaper MachineProduct Description:

The T-Shape Ear Type Baby Diaper Machine is a revolutionary solution for the production of high-quality baby diapers.

This machine is designed with advanced technology and precision engineering to ensure efficient and reliable performance. It is capable of producing diapers with T-shaped ears, providing a comfortable fit for babies of all sizes. The machine is constructed using durable materials and is built to withstand the rigors of continuous production.

T-Shape Ear Type Baby Diaper Machine Technical Features:

1. High Speed: The T-Shape Ear Type Baby Diaper Machine operates at a high speed, allowing for increased production output.

2. Adjustable Size: This machine has the flexibility to produce diapers in different sizes, catering to the diverse needs of babies.

3. Automatic Control System: Equipped with an advanced automatic control system, the machine ensures precise and consistent production processes.

4. Easy Operation: The user-friendly interface of the machine makes it easy for operators to set parameters, monitor production, and troubleshoot any issues that may arise.

5. Energy Efficiency: The machine is designed to minimize energy consumption, reducing operational costs and environmental impact.

T-Shape Ear Type Baby Diaper Machine Product Application:

The T-Shape Ear Type Baby Diaper Machine is widely used in the manufacturing industry for the production of high-quality baby diapers. It is an essential machine for diaper manufacturers, enabling them to meet the growing demand for comfortable and reliable products.

T-Shape Ear Type Baby Diaper Machine Main Functions:

1. Diaper Formation: The machine efficiently forms the diaper structure, including the absorptive core, inner and outer layers, and the T-shaped ears for optimal fit.

2. Elastic Waistband Application: It incorporates an elastic waistband for added comfort and secure fit, enhancing the overall performance of the diaper.

3. Side Sealing: The machine effectively seals the sides of the diaper, preventing leakage and ensuring maximum protection for babies.

4. Cutting and Stacking: Once the diaper is formed and sealed, the machine precisely cuts and stacks the finished products for easy packaging and distribution.

T-Shape Ear Type Baby Diaper Machine Precautions:

1. Proper Maintenance: Regular maintenance of the T-Shape Ear Type Baby Diaper Machine is essential to ensure optimal performance and prolong its lifespan.

2. Operator Training: Operators must receive adequate training on machine operation and safety protocols to avoid accidents and maximize productivity.

3. Quality Control: Continuous monitoring and inspection during production are crucial to maintain high-quality standards and identify any defects or issues promptly.

4. Compliance with Regulations: Adhering to local regulations and safety standards is essential when operating the machine to ensure the safety and well-being of both operators and end-users.

T-Shape Ear Type Baby Diaper Machine

|

No. |

Raw materials |

|

1 |

Hydrophilic NW (Topsheet) |

|

2 |

Hydrophobic NW (Legcuff) |

|

3 |

Elastic for Legcuff |

|

4 |

ADL |

|

5 |

Fluff pulp |

|

6 |

SAP |

|

7 |

Upper tissue/NW |

|

8 |

Lower tissue/NW |

|

9 |

Pe film |

|

10 |

NW for laminating |

|

11 |

Frontal tape |

|

12 |

Elastic NW for big ear |

|

13 |

NW for small ear |

|

14 |

Magic side tape |

|

15 |

Construction glue |

|

16 |

Elastic glue |

|

17 |

Wetness indicator glue |

The U-Shape Baby Diaper Production Line incorporates advanced technology and engineering expertise to provide a comprehensive solution for diaper manufacturers....

Overall size: 38mx8mx5m (for reference only), Driven system: Servo drive, digital size change, ensure run synchronously at full process.Safety system: Safety guard for operating side, emergency s...

This isMenstrual Pad Machine, also can produce adult pant machine from this machine. The structure is pulp type and ultra thin type, with dual legcuff, can...

This is Sanitary Pad Machine in Nigeria. The machine stable speed is 800pcs/min. This machine can produce two sizes of the sanitary pad, this machine also...

Our operational costs have decreased significantly, thanks to the efficiency of the Baby Diaper Machine. It's a cost-effective solution for any diaper manufacturer.Matthew 2024-05-30

The Baby Diaper machine technical support provided by the manufacturer has been excellent, ensuring that our production runs smoothly without any hiccups.amy 2024-05-30

The Baby Diaper Machine is easy to operate and requires minimal maintenance, saving us time and resources. It's definitely worth the investment.Ethen 2024-05-30

With the Baby Diaper Machine, we've been able to expand our product line and meet the growing demand for baby diapers. Our customers are happy, and so are weLiam 2024-05-30